Han’s Laser Benefits of full automation

Enhancing Han’s Laser Efficiency and Reliability through Automation.

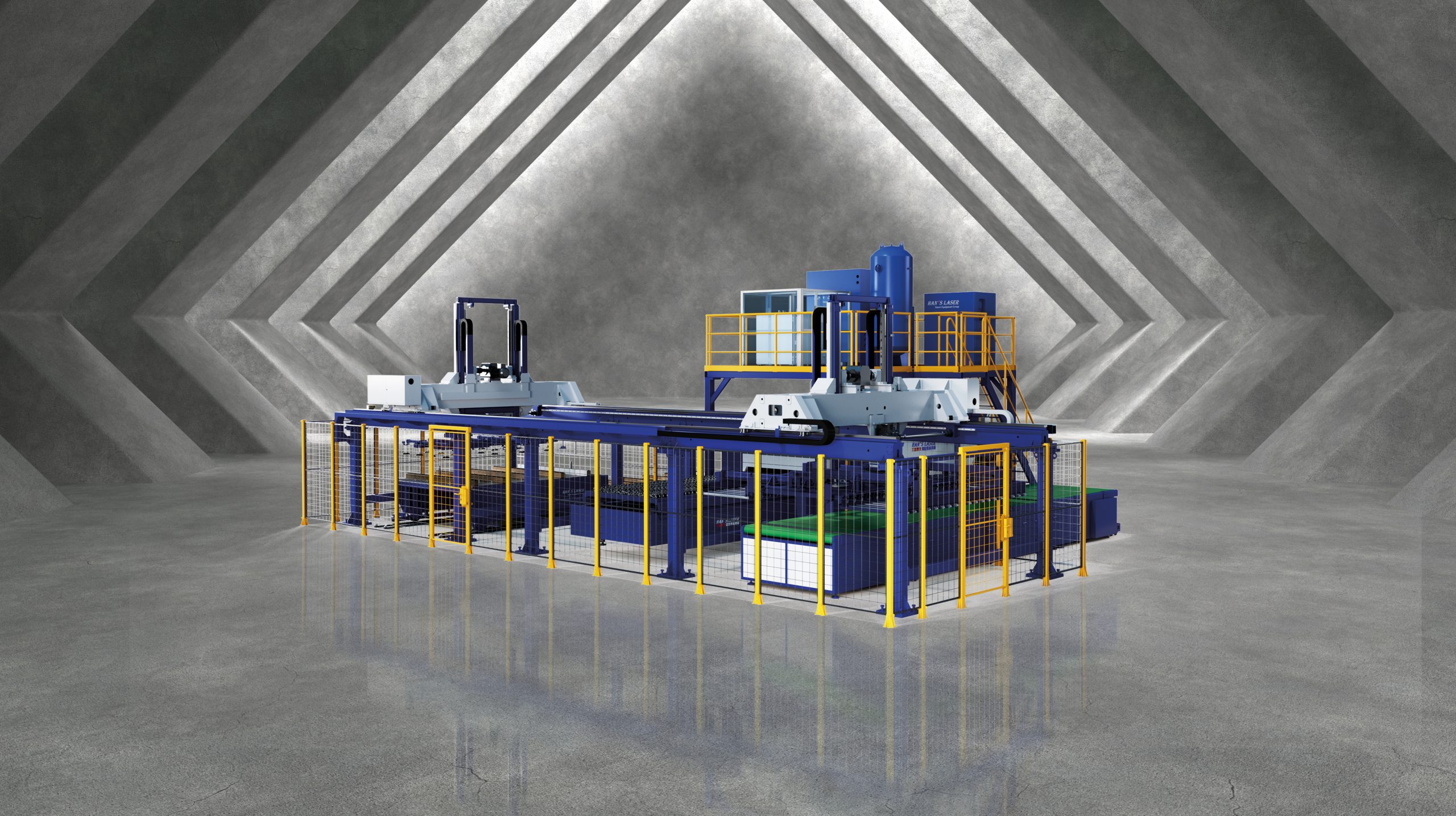

Automation Systems for Laser Cutting Machines Made by Han’s

-

Automating Han’s Laser Production Processes to Increase Efficiency

In today’s manufacturing environment, efficiency and precision are critical. Automation systems for Han’s laser cutting machines promise to revolutionize the way industrial processes are carried out. These methods are intended to decrease manual labor, improve precision, and streamline production. This is a detailed look at the ways that automation solutions for Han’s laser cutting machines are changing the manufacturing sector.

Increasing Accuracy and Effectiveness

-

Han’s Laser Minimize Labor dependency.

The automated systems for Han’s laser cutting machines are designed to achieve previously unheard-of levels of accuracy and productivity. These systems guarantee that every step of the cutting process is carried out with remarkable accuracy by automating material loading, laser processing, sorting, and material unloading, among other processes. This accuracy is very helpful, especially in fields where the end product’s quality and consistency are crucial.

Adaptable and Scalable Approaches

-

Han’s Laser Reduce Downtime with Full Automation

Scalability and adaptability are two features that Han’s laser automation systems are built with in mind. These solutions are able to expand with your company and change to meet the changing requirements of your working environment. There is a solution that works for you, regardless of the size of your business or industrial facility. Furthermore, Han’s Laser provides configurations that, in comparison to standard laser automation installations, use 30% less floor space, offering important space efficiency in your company.

Customized Knowledge for Optimal Output

-

Han’s Laser Robust and Adaptable Automation Systems.

You may take advantage of the knowledge and experience of Han’s laser automation professionals to get the most out of their laser cutting machine automation solutions. These professionals work with you to identify the best configuration for laser technology, material supply, storage, removal, and part sorting.

In conclusion, Han’s laser cutting machine automation systems lead the manufacturing sector in accuracy and productivity. They are now necessary tools for companies trying to streamline their production procedures and maintain their competitiveness in a market that is changing quickly since they cut down on labor costs, minimize downtime, and provide flexible solutions.