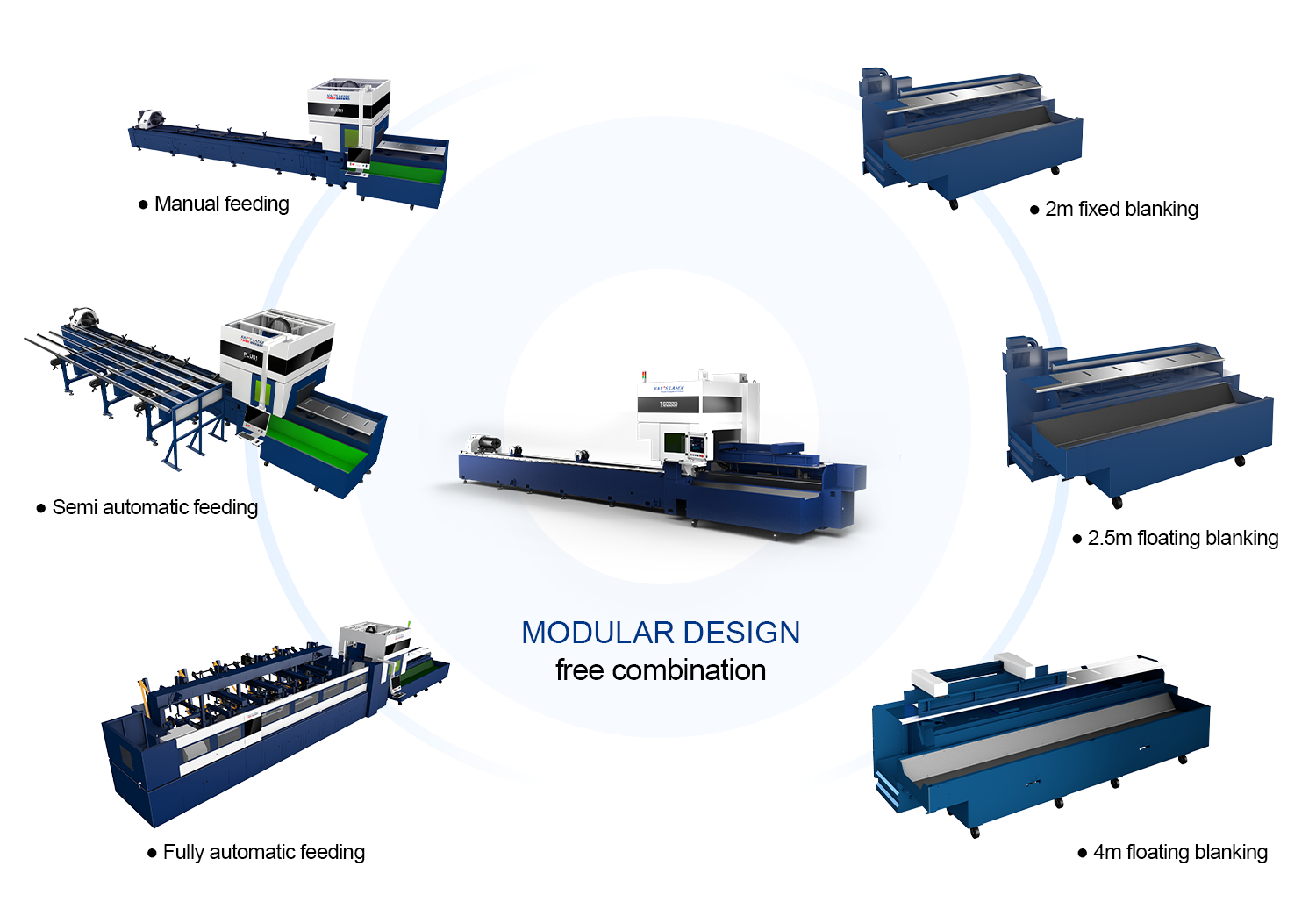

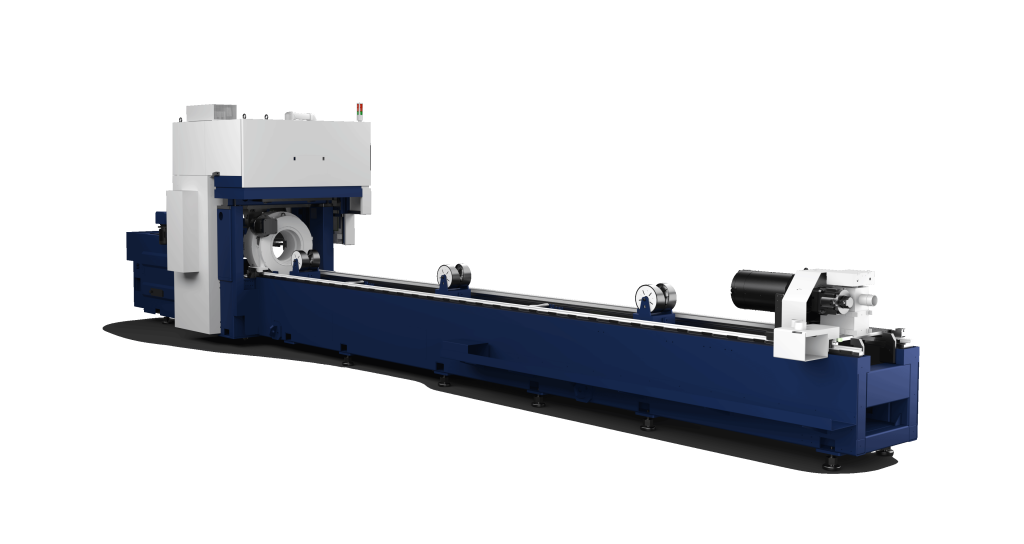

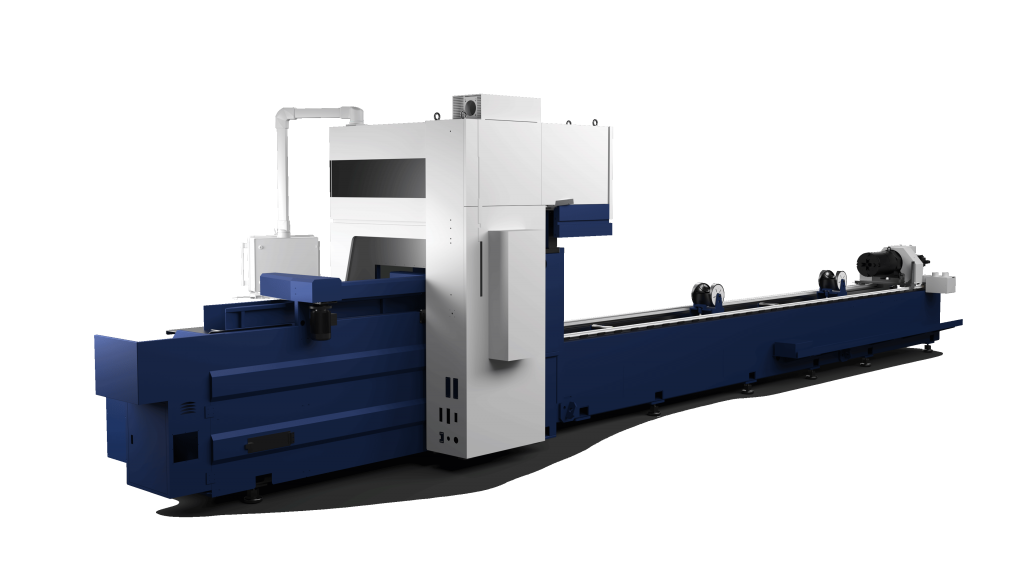

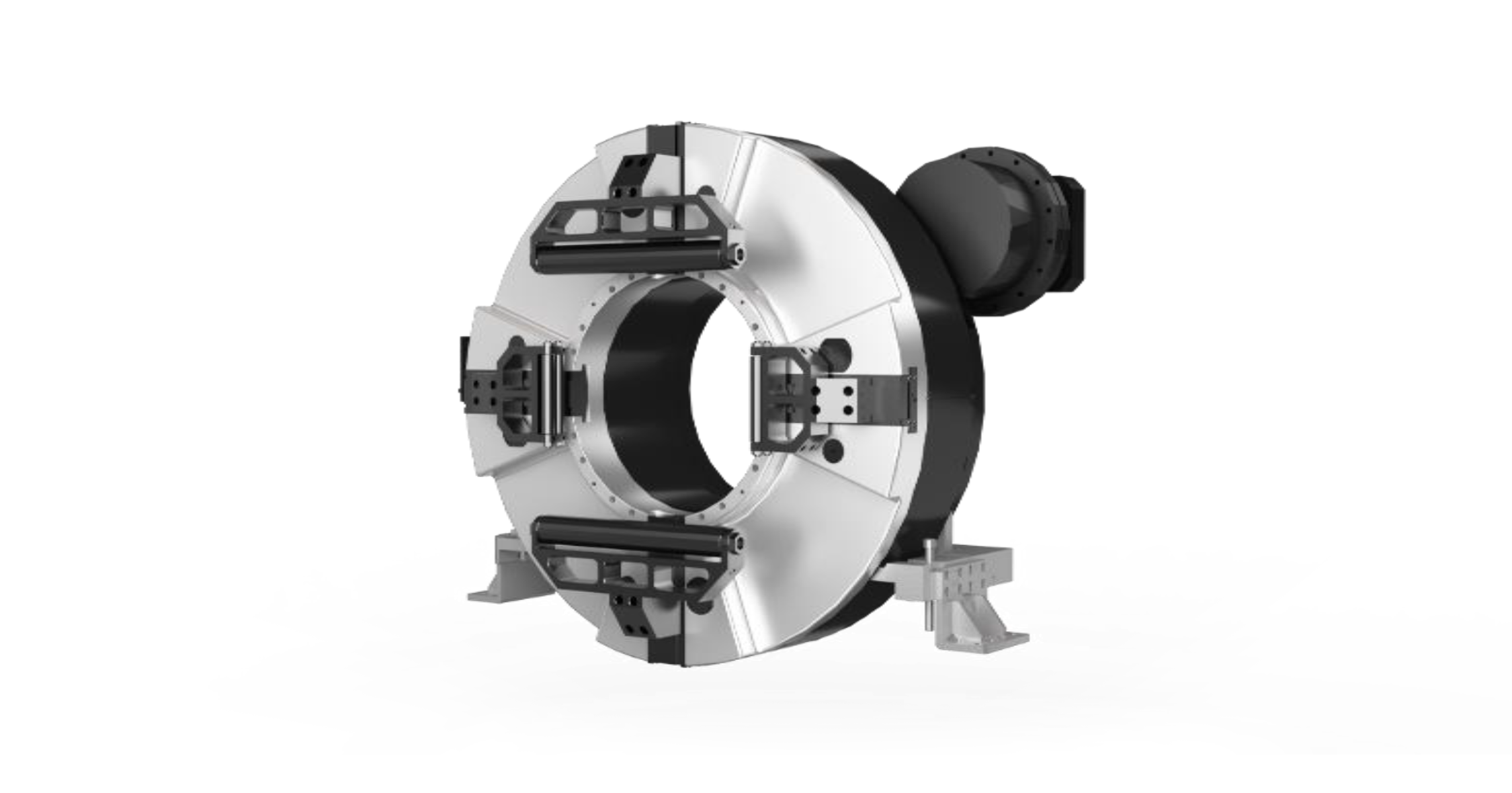

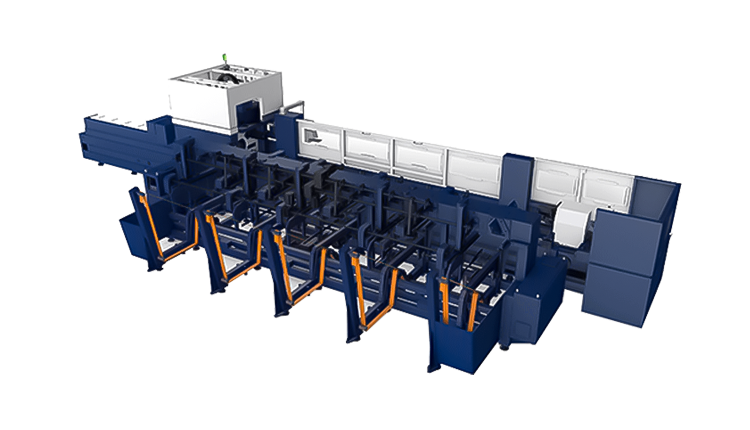

- Han’s tube laser series uses mix and match modular loading and unloading structure.

- This modular combination brings users munch more flexibility to fit their own needs.

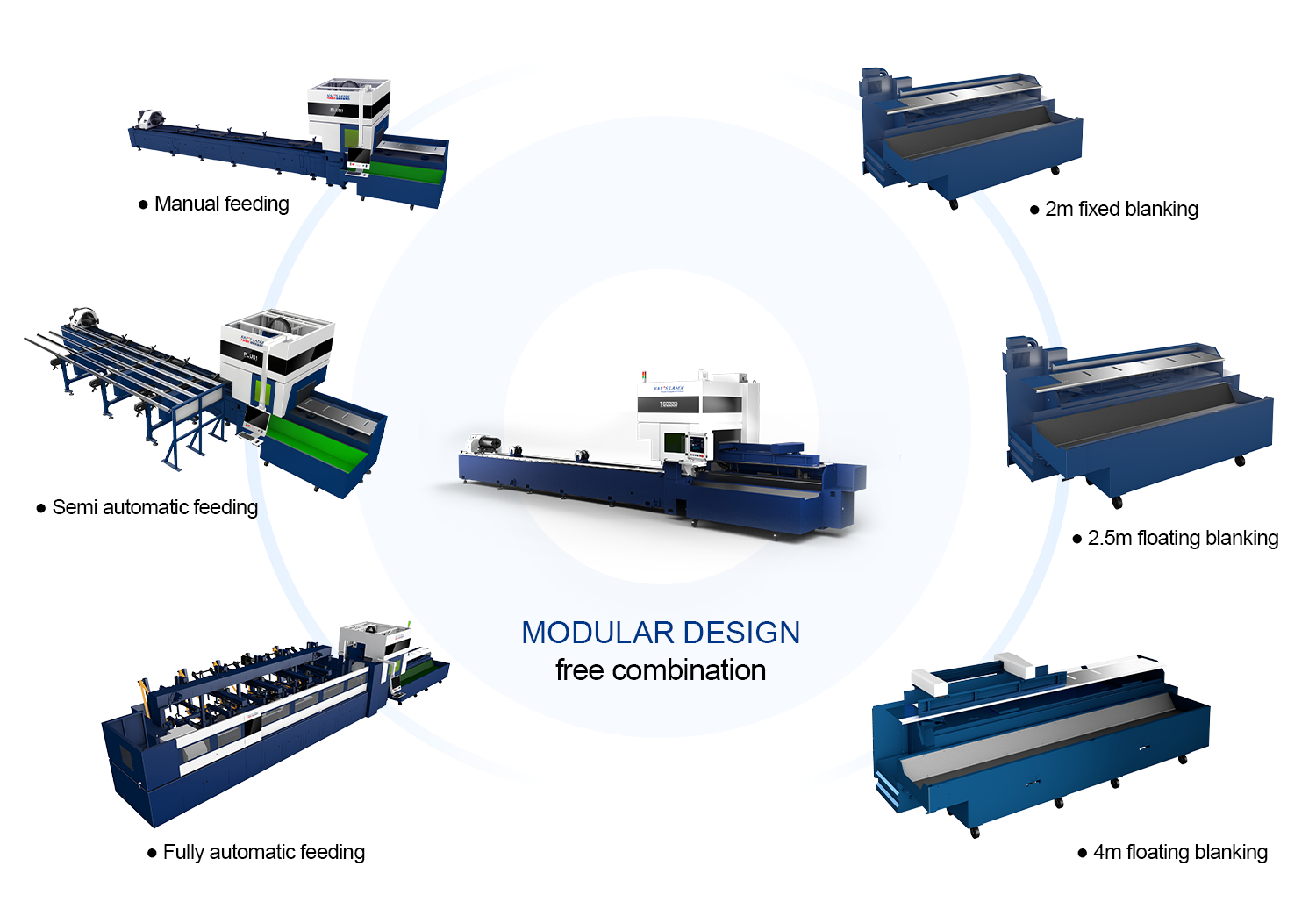

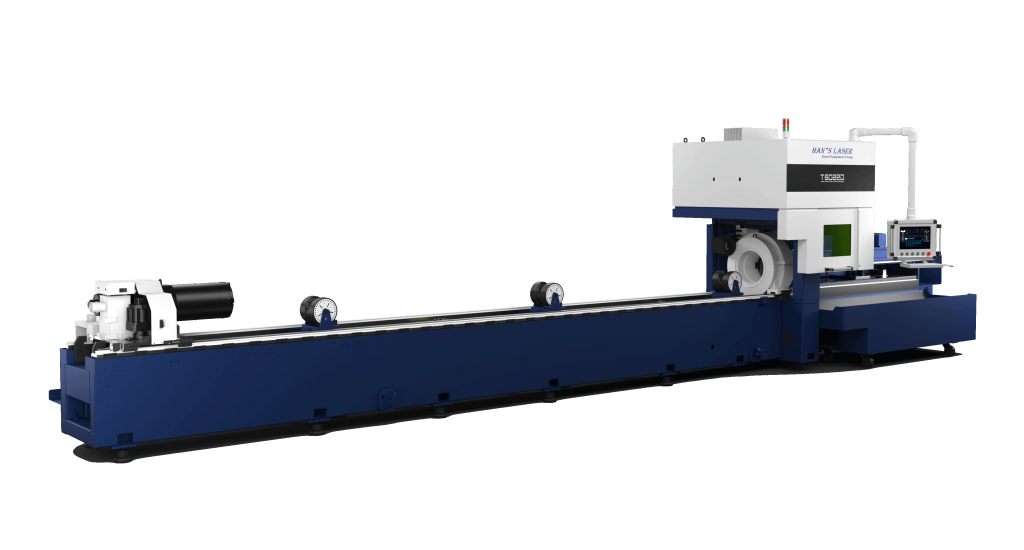

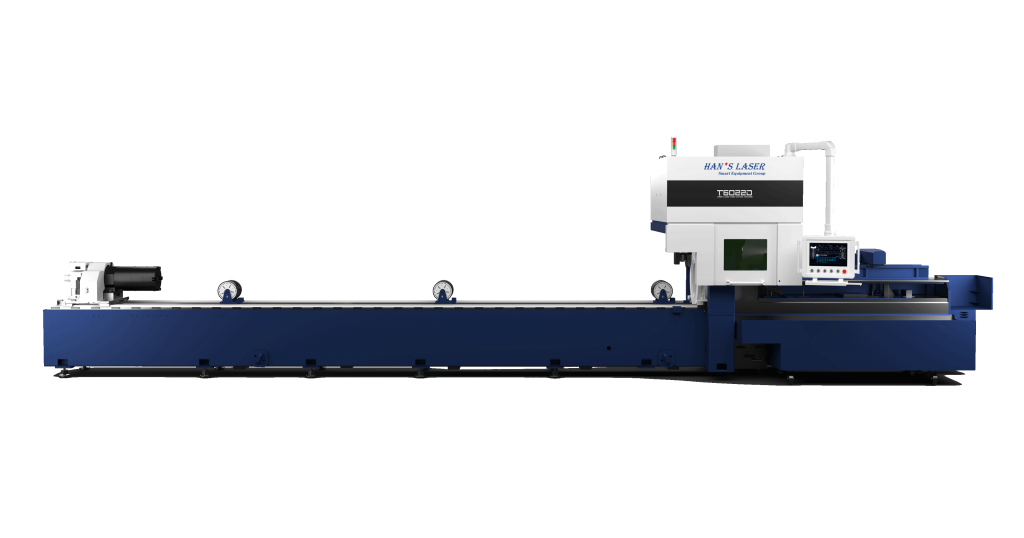

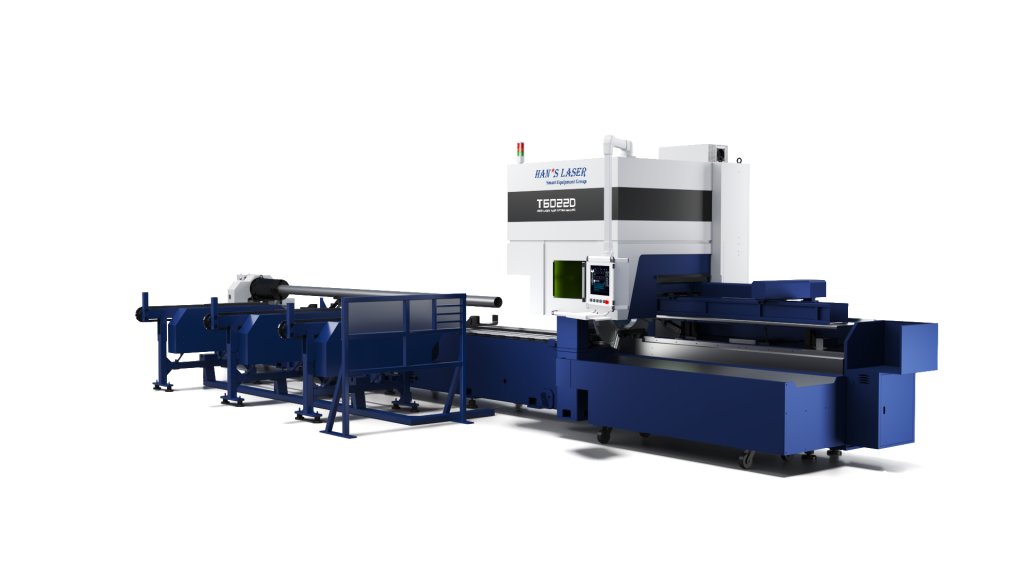

This series of pipe cutting machine is a high-power CNC professional laser pipe cutting machine with international standards developed by Han’s Laser Smart Equipment Group Co., Ltd.

This series is characterized by professionalism, high speed, high precision, high efficiency, and highcost performance. It is the preferred cutting machine in the metal pipe processing industry.

HORIZONTAL WELDING BED:

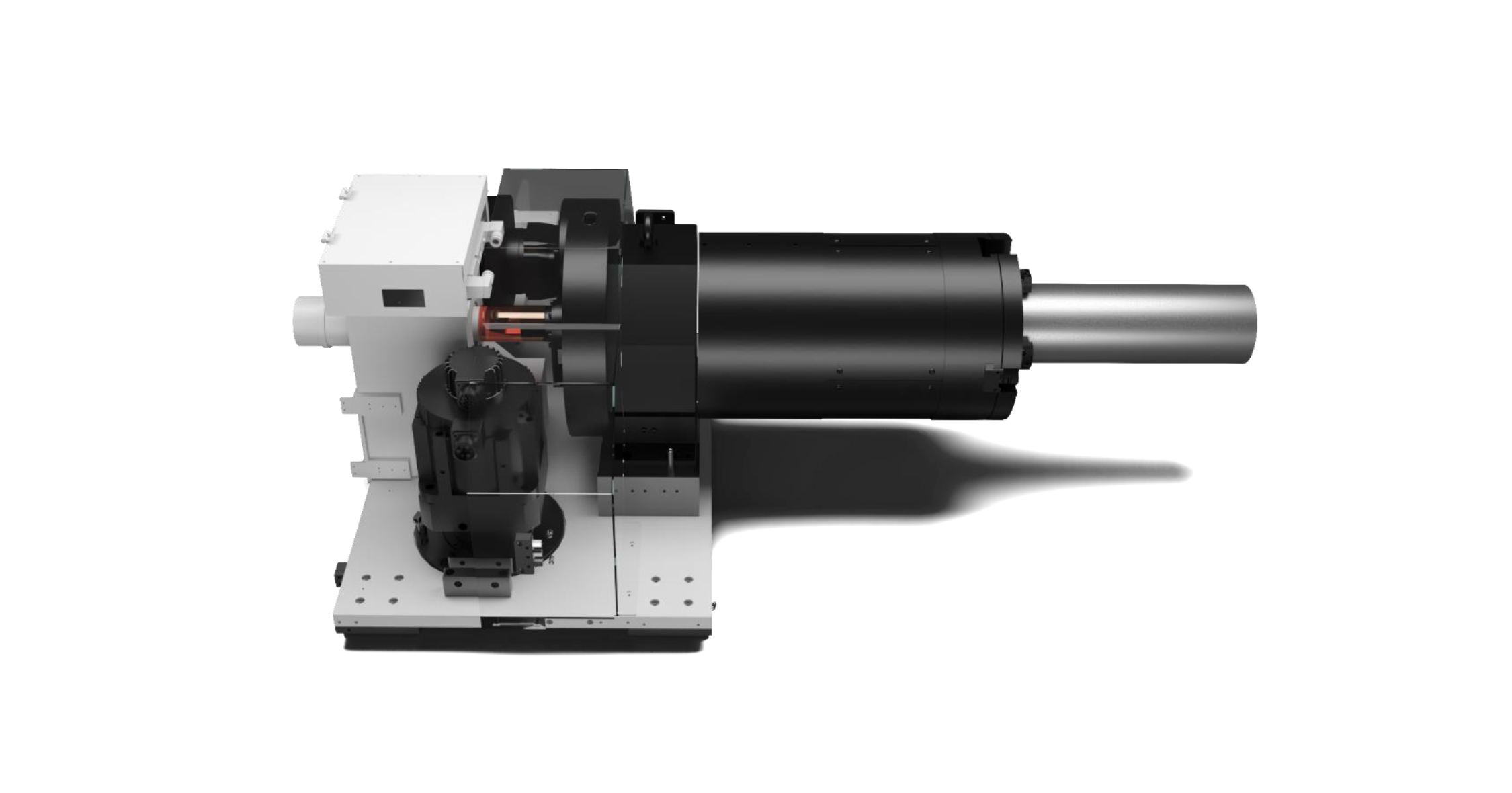

HAN’S CUTTING HEAD:

INTELLIGENT REMOTE CONTROL DEVICE:

Provide series cutting modules, save time, material and no-worry in pipe cutting.

| 3015HF | 4020HF | 6025HF | 8025HF | 10025HF | 12025HF | 12030HF | UNITS | |

| Machine Length | 9615 | 11230 | 15700 | 19200 | 24100 | 28400 | 28400 | mm |

| Machine Width | 3040 | 3470 | 4060 | 4060 | 4230 | 4230 | 4800 | mm |

| Machine Height | 2330 | 2320 | 2400 | 2400 | 2610 | 2610 | 2610 | mm |

| Nominal Sheet Size (X) | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 | 12000 | mm |

| Nominal Sheet Size (Y) | 1500 | 2000 | 2500 | 2500 | 2500 | 2500 | 3000 | mm |

| X Axis Stroke | 3050 | 4030 | 6030 | 8100 | 10100 | 12100 | 12100 | mm |

| Y Axis Stroke | 1530 | 2020 | 2520 | 2520 | 2600 | 2600 | 3080 | mm |

| Z Axis Stroke | 120 | 120 | 400 | 400 | 400 | 400 | 400 | mm |

| X/Y Positioning Accuracy | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.05 | ±0.05 | ±0.05 | mm/m |

| X/Y Repositioning Accuracy | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.05 | ±0.05 | ±0.05 | mm |

| Max. Travelling Speed | 200 | 200 | 160 | 160 | 160 | 160 | 160 | m/min |

| Max. Accelerating Speed | 2.8 | 2.8 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | G |

| Max. Workbench Weight | 1800 | 3200 | 14400 | 19200 | 24000 | 28800 | 34400 | kg |

| Machine Weight (Approx.) | 10000 | 14000 | 20000 | 24000 | 29000 | 32000 | 34000 |

kg |

The right to make changes to dimensions, construction, and equipment is reserved. ISO-9001-certified.

The technical data can vary based on the chosen configuration of the machine.

| Cutting Head | Hans / Precitec/MAX Photonics | |||||||

| Focus Mode | Automatic | |||||||

| Cooling Mode | Water Cooled | |||||||

| Piercing Mode | 5 Stage | |||||||

| Laser Source | IPG (USA / Germany)/ MAX Photonics/ Han’s Laser Photonics (China) / Coreactive (Canada) | |||||||

| Rack | Gudel (Switzerland) | |||||||

| Pinion | Rexroth (Germany)/Hiwin(Taiwan) | |||||||

| Speed Reducers | Alpha (Germany)/Gudel (Switzerland)/Stober(Germany) | |||||||

| Servo Drives & Motors | Rexroth (Germany) | |||||||

| Computer | Industrial X64-based PC | |||||||

| Operating System | Windows 10 64 bit | |||||||

| CNC Software | Han’s 901 (Bosch Rexroth) | |||||||

| Display Size | 21” | |||||||

| Electrical System | Airtac/Parker | |||||||

| Gas Circuit Control – Oxygen, Nitrogen and Air | Lanny (Germany) | |||||||

| Laser and Cutting Head Cooling Device | Dual Circuit Industrial Chiller | |||||||

| Laser Source Enclosure | Han’s Laser | |||||||

The technical data can vary based on the chosen configuration of the machine.

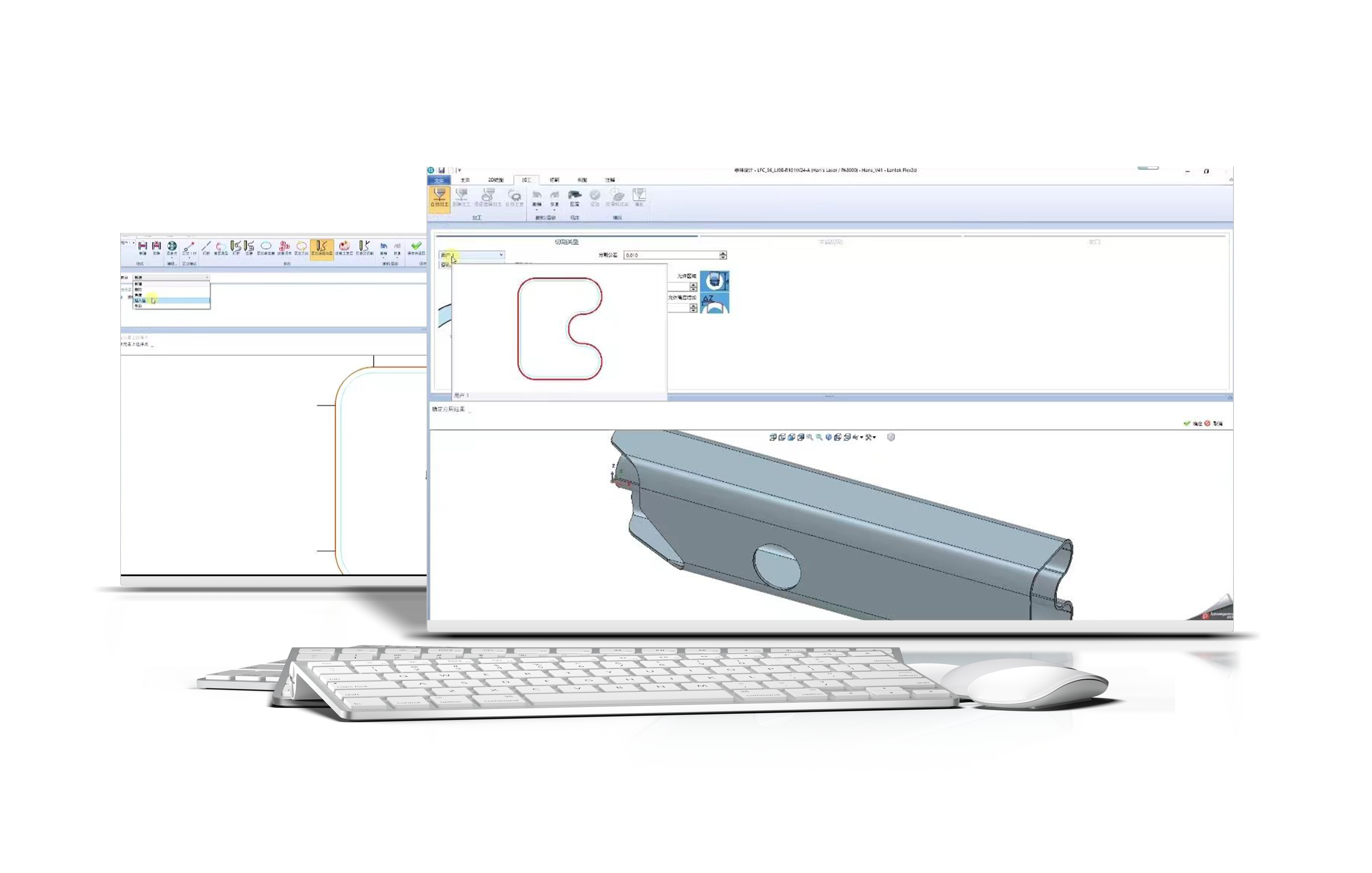

Adopt “Han’s SMC” open CNC system, which is based on Windows 10 Chinese and English operation interface, has the characteristics of high reliability, high performance, intelligence and networking, high cost performance, simple operation and convenient use.

Pipe surface height tracking control (follow-up function).

Laser power gradient control.

Automatic calibration function of height sensor.

Common edge cutting function.

Pulse cutting control functionat corners.

Special cutting function of lead-in line.

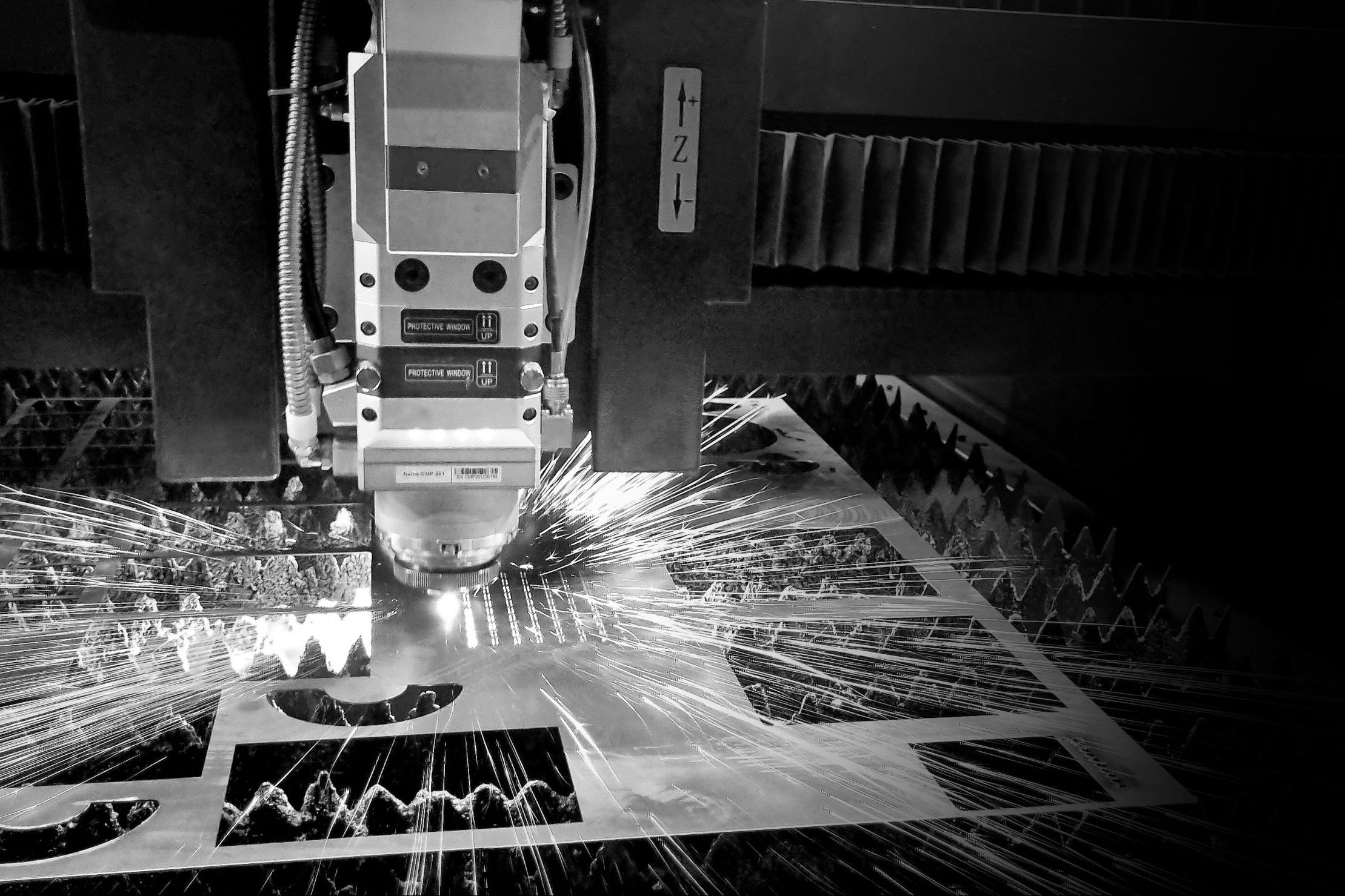

IPG Photonics is the world leader in fiber laser technology. The beam is of the highest quality, allowing constant cutting with extreme precision.

IPG features a compact, water-cooled, modular design, which allows for easy maintenance and relocation as required. IPG also boasts a class-leading wall plug efficiency of 50%, making them the industry standard for good reason.

Key components are tested or burned-in for hundreds of hours, and in the end, IPG only use the best components that have passed stringent control standards. IPG Photonics is certified ISO 9001:2008, giving customers the assurance that their business processes are both well-documented and conform to the same standards of quality upheld by most of the world’s largest and most highly regarded companies.

Maxphotonics Multi-Module CW Fiber Laser adopts water cooling, modular design, compact structure, highly integrated system, maintenance-free and high reliability.

The laser power is continuously adjustable, with high electro-optical conversion efficiency , high beam quality , and high laser stability. It is an ideal laser source for thick plate laser cutting, laser welding, laser cladding, surface heat treatment and other applications.

CW Fiber Laser adopts optical fiber with QBH head output CW Fiber Laser adopts optical fiber with LOE head output, which can be used with laser processing heads, galvanometers, etc,for system integration with robots and machine tools. It is widely used in hardware, medical, automotive, marine, aviation, Construction machinery and other industry.

The fiber laser independently developed by Han’s Laser has the advantages of large heat dissipation area, good beam quality, small size, etc. Compared with the gas laser and solid laser, it has obvious advantages, and has gradually developed into an important candidate in high-precision laser processing, laser radar system, space technology, laser medicine and other fields.

As the optical path of the fiber laser can be coiled, the optical path takes up less space. When the single core semiconductor pump laser is used as the pump source, the pump laser can be installed in a decentralized manner, with good heat dissipation characteristics. When the installation density is not high, air cooling can be used. When the installation density is high, only a small amount of water can meet the heat dissipation requirements. Therefore, all fiber lasers are smaller and lighter than gas and solid laser systems with the same output power.

The whole system adopts high end components to ensure the highest speed transmission while maintaining precision, stability, low failure rate and long service life.

Excellent internal quality achieves high standard machining dimensional accuracy, ensuring long-term stable operation of the equipment.

Desboer

Desboer high precision reducer, with high precision, high torsional stiffness, high reliability, low noise and longer service life, is more suitable for long-term high speed operation applications.

Roust World

Roust precision linear guide rail has built a complete set of high-precision transmission system. Excellent internal quality has achieved high standard machining dimensional accuracy, and ensured the long-term stable operation of the equipment.

K.H/YYC/Wolfer

K. H/YYC precision helical rack, wear-resistant, high precision, smooth operation, better stability, can maintain accuracy for a long time and prolong service life.

Innovance Servo Motor

Inovance high-end servo motor meets the requirements of high speed, high precision, high quality and high productivity.

Work process of laser tube cutting machine: the tube bundle is hoisted to the loading part, the loading unit steadily conveys raw materials to additional support devices of the machine bed by a number of processes, including material loading, separating, hooking, lifting, length measuring, clamping, and feeding.

The height of the support devices is servo adjusted based on the tube dimension. The feeding chuck moves to a position which is automatic measured based on the raw material length, clamp the material, and send the material to the cutting area for end trimming.

Finally, cutting is performed according to the nesting program prepared by the automatic programming software. Each cut work piece slides down to the finished product box next to the operator, and the work pieces are manually collected into the designated finished product material box.

While cutting the tube, the next tube will be automatically prepared at the same time in the loading part. After the previous pipe material is processed, the subsequent tube will be sent immediately. The equipment will complete the loading action instantly, and the pipe will quickly enter the cutting process, which greatly improved production efficiency.

The semi automatic feeding module can be installed on the front of the machine, which makes it easy to put pipes on shelves in batches and greatly reduces the preparation time of raw materials.

The fully automatic feeding module can be installed on the back of the machine, and the raw material stacking rack can automatically provide pipes, thus significantly improving the loading speed and production efficiency.