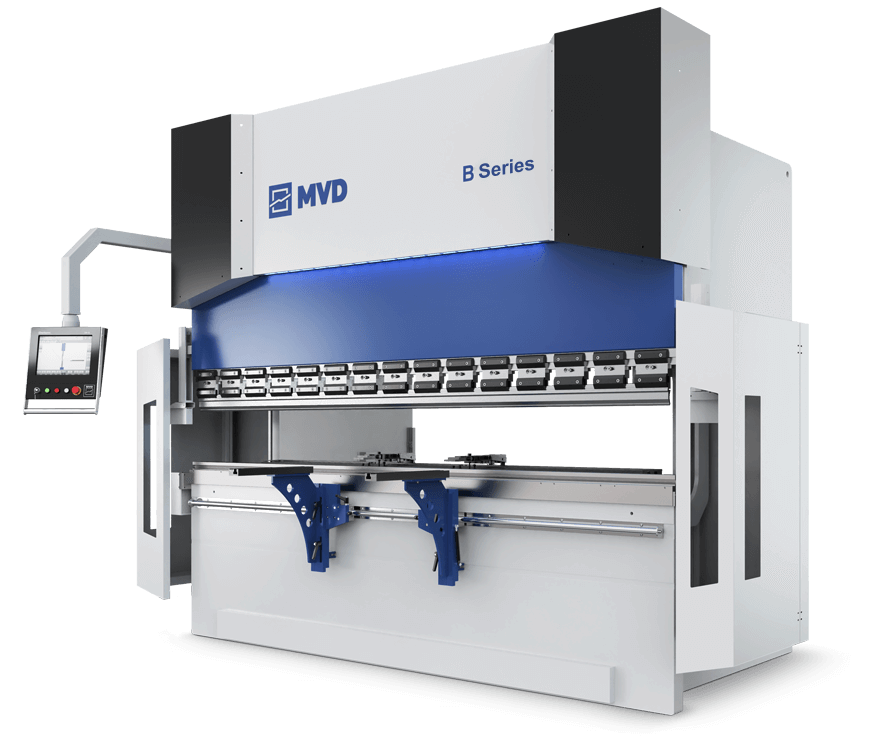

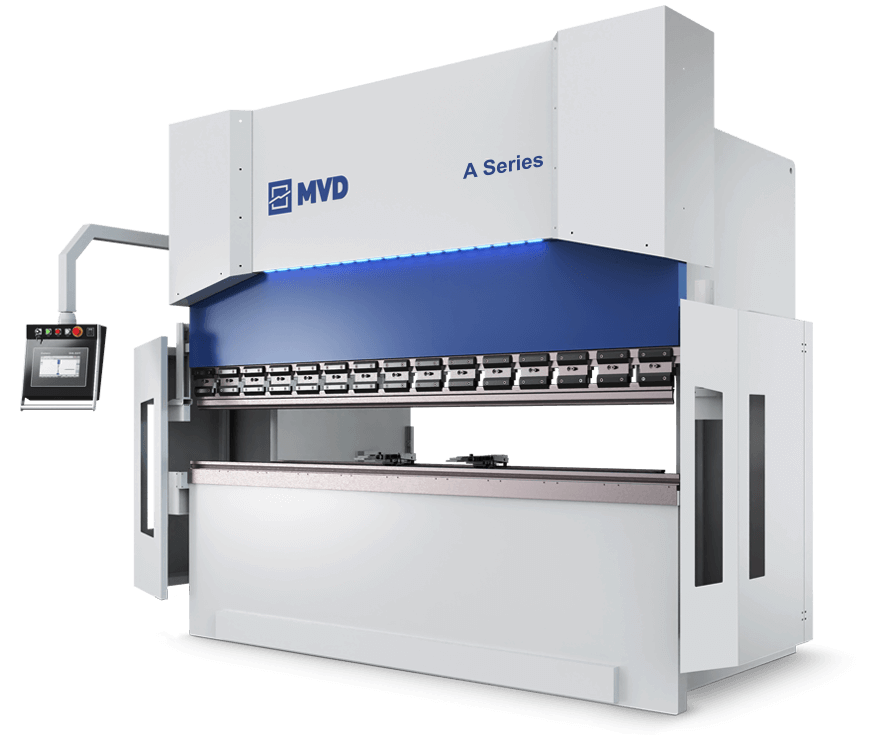

MACHINE FEATURES:

– Y1, Y2, X CNC 3 axes

– 210mm stroke, 410mm throat depth

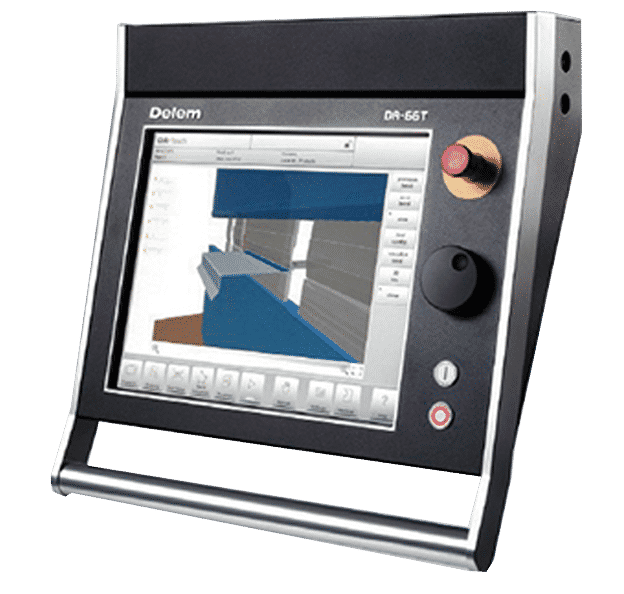

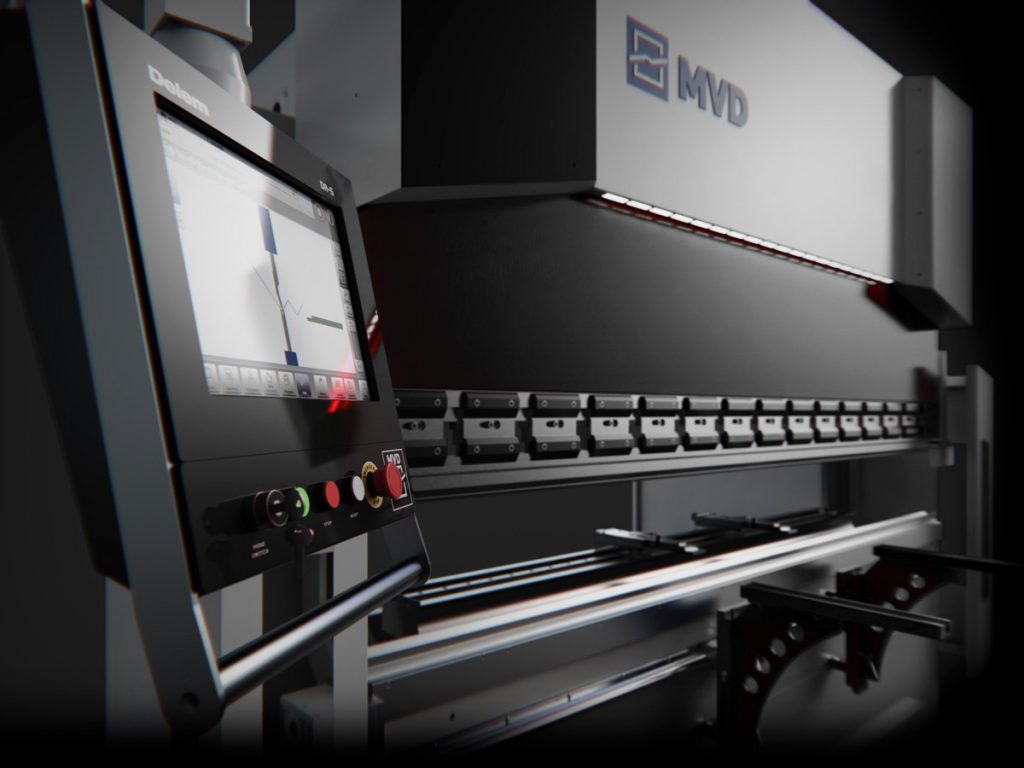

– ESA S530 CNC control unit

– ± 0.03mm accuracy AC motorized with inverter and back-gauge

– Manual PROMECAM punch tool holder

– European-designed MVD special narrow bottom table

– Standard punch tools (H: 67, 85°, R:08)

– Standard die tools (60 x 60mm, 4 Vee V=-50mm, 85°, H:60)

– High-quality and precision linear scales

– LED illumination on RAM

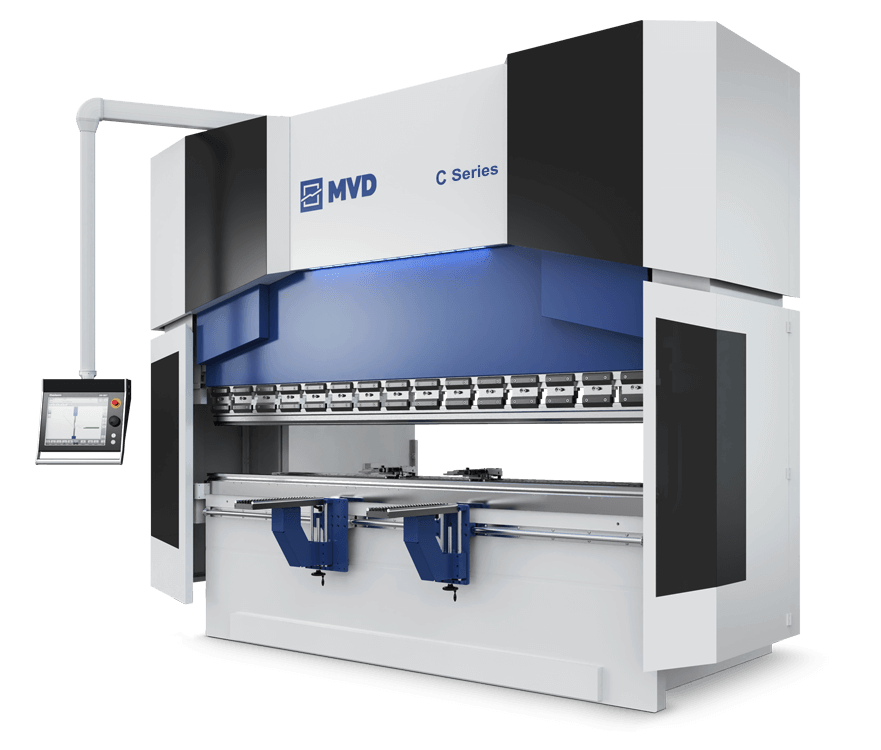

OPTIONAL FEATURES:

1. R axis back-gauge

2. Sliding front-sheet support arms

3. Wide bottom table for multi-vee dies

4. Anti-deflection crowning with original WILA wedges

5. AKAS or DSP front-laser safety systems

6. Rear safety

7. Additional back-gauge fingers

– Plus more