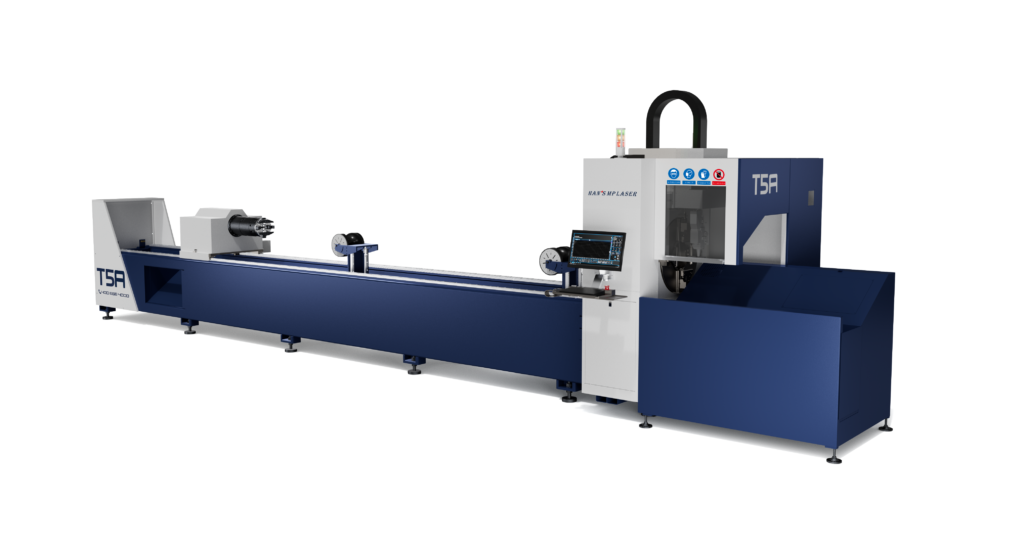

meet the HAN’S LASER MPS-T5A series

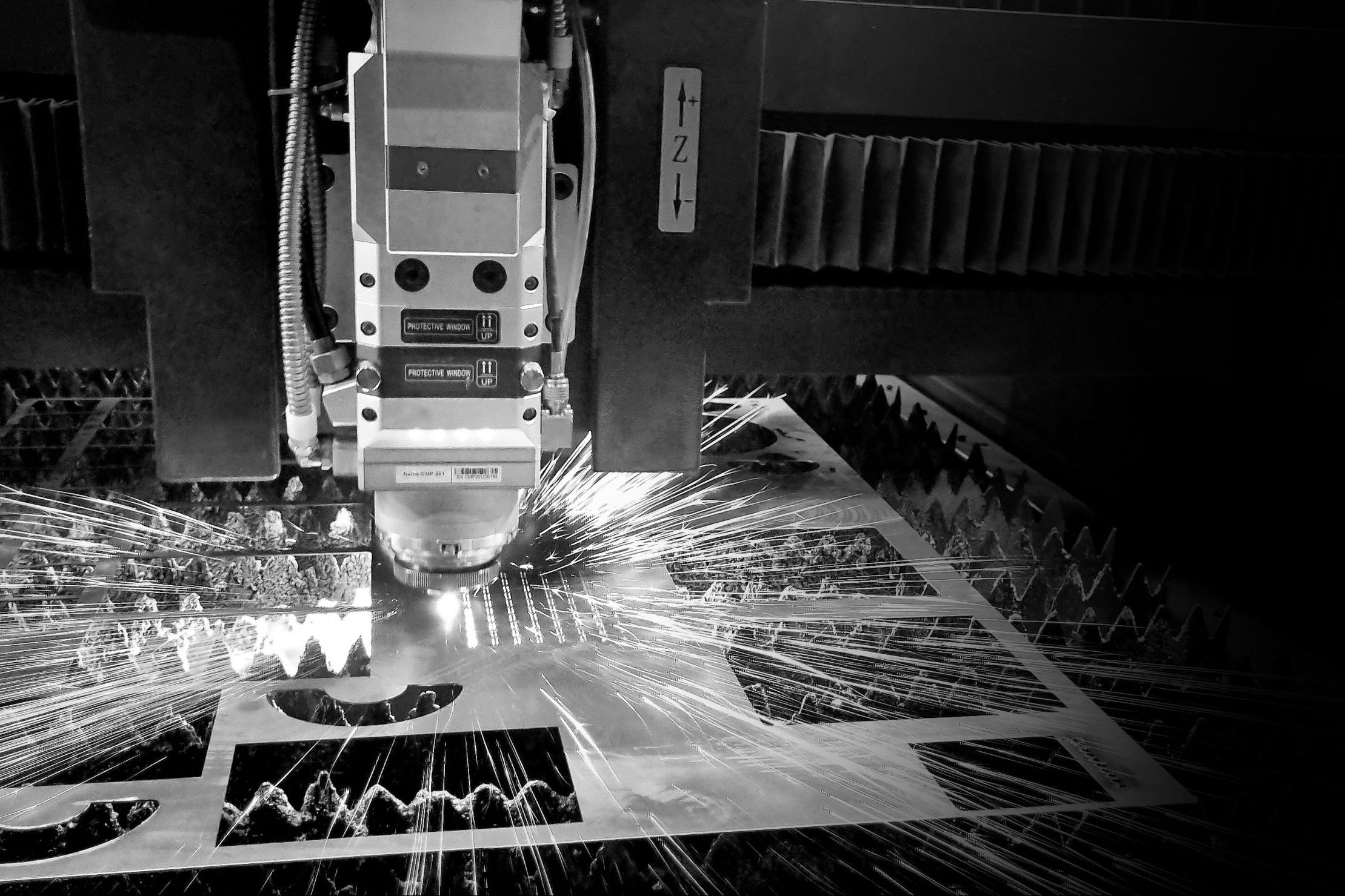

MPS-T5 series is a new generation of laser cutting machine specially used for cutting various metal thin-walled square tubes, circular tubes, I-beams, angle steels, and symmetric special-shaped pipe fittings. The Han’s MPS-T5A is a professional pipe cutting machine with superior performance for the price.

Benefits

- Efficient: Push type pipe cutting mode, improving processing efficiency.

- R&D: Independent research and development of high-tech pneumatic chuck.

- Stable Structure: The main bed is bent and welded with high-quality plates, with stable structure.

- Large Range of Tubes: Large range of cutting diameters (φ15-210mm) and variety of tubes.

- High Precision: Imported servo motor drives to ensure high-speed, high-precision and reliable operation of the equipment.

Details

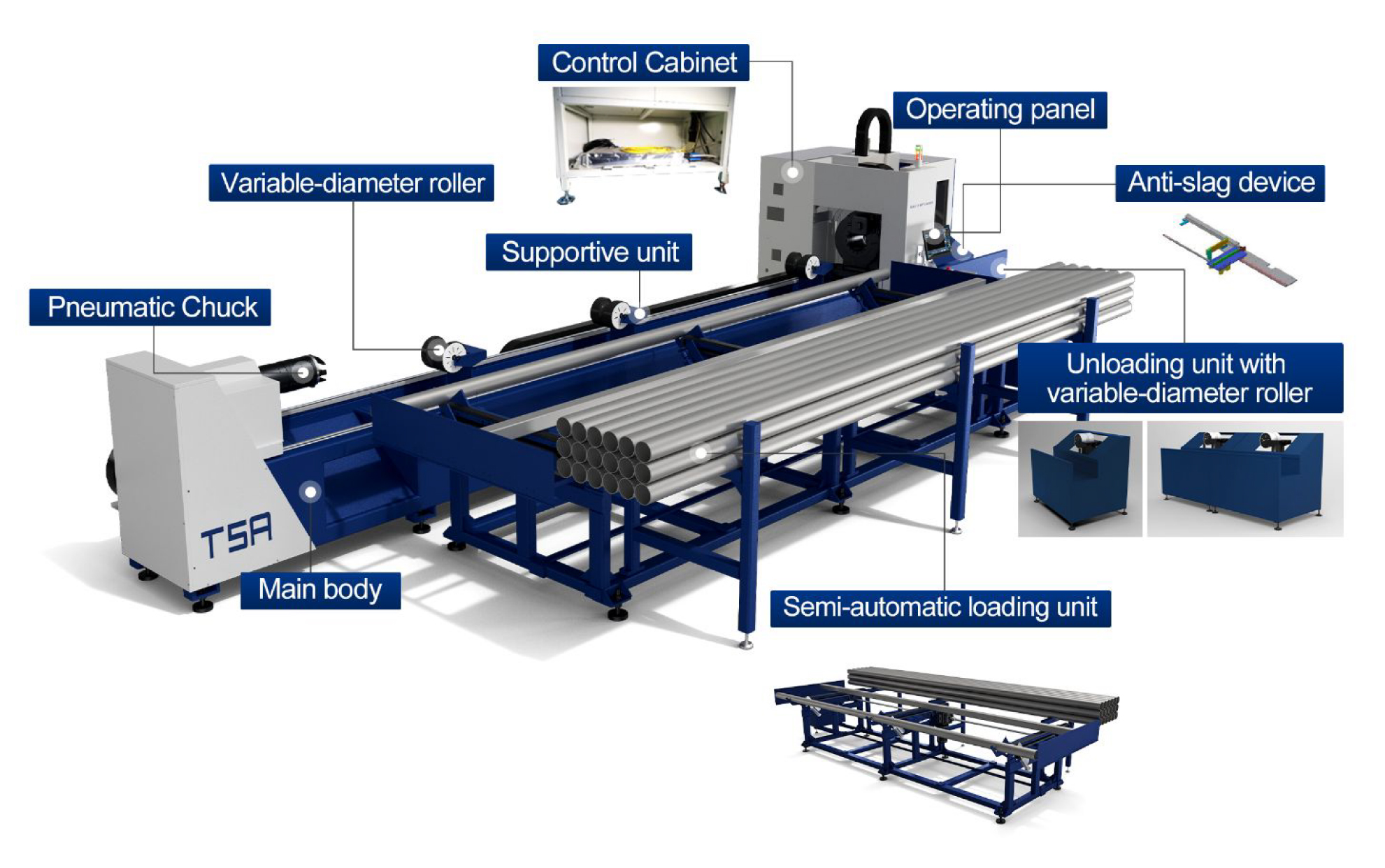

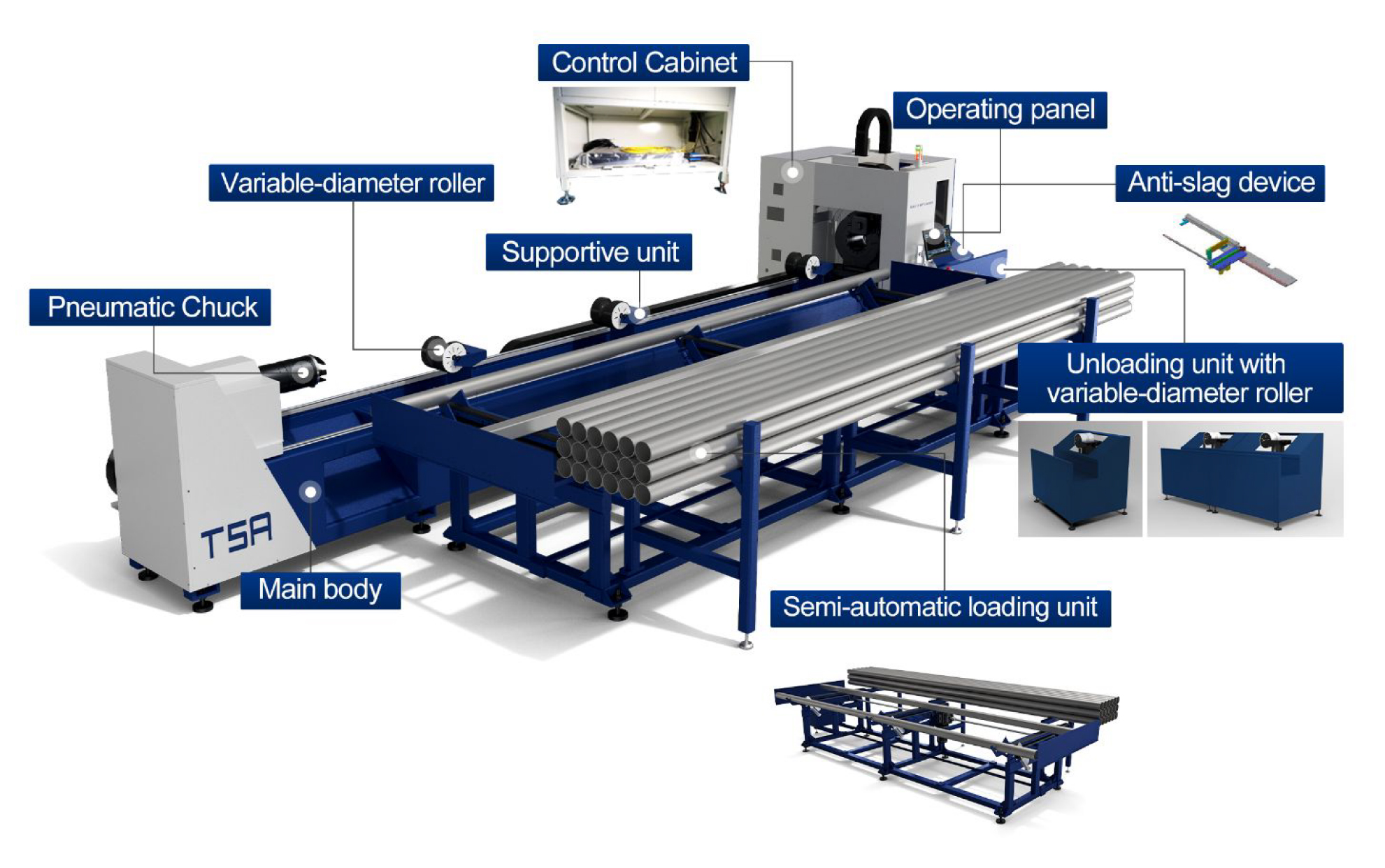

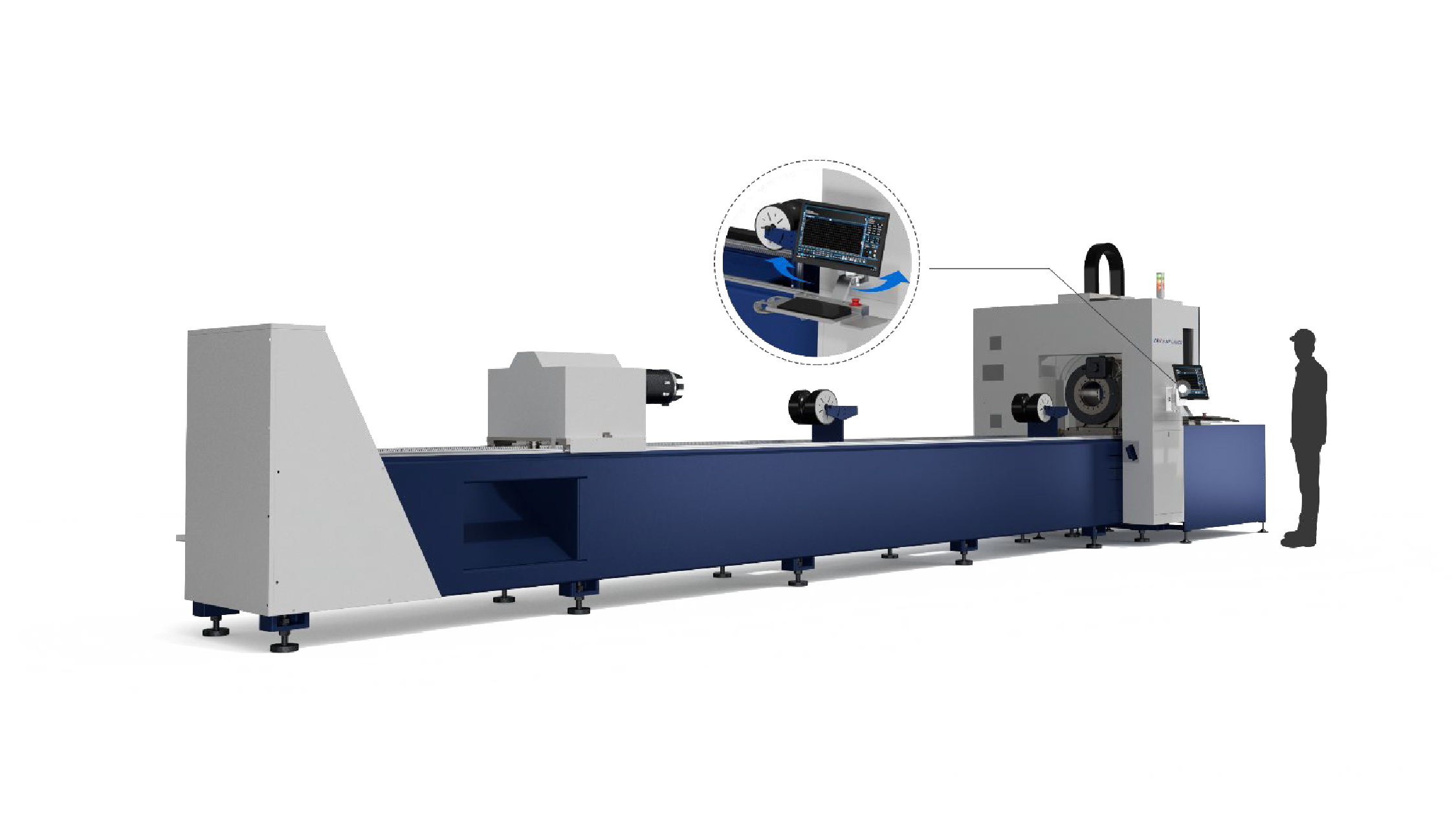

COMPLETE MACHINE STRUCTURE:

Stable and compact structure with integrated operation panel and ancillary components. This helps reduce factory footprint and save floor space while protecting the critical components.

Specs

| Standalone Machine | MPS -T5A | Units |

| Machine Length | 10000 | mm |

| Machine Width | 2300 | mm |

| Machine Height | 2500 | mm |

| Max. X Axis Speed | 100 | r/min |

| Tailing Length | ≥80 | mm |

| Round Tube Cutting | Φ15 – Φ220 | mm |

| Square Tube Cutting | 15 – 150 | mm |

| X/Y Positioning Accuracy | ±0.05 | mm/m |

| X/Y Repositioning Accuracy | ±0.05 | mm |

| Max. Travelling Speed | 110 | m/min |

| Max. Accelerating Speed | 1.0 | G |

| Max. Machine Weight | 9500 | G |

| Max. Single Tube Cutting Weight | 150 | kg |

| Max. Tube Cutting Length | 6500 | mm |

| Max. Standard Outfeed Length | 1500 | mm |

| Option Outfeed length | 3000 | mm |

| Semi Auto Feeder | ||

| Max. Loading Weight | 4900 | kg |

| Max. Single Tube Cutting Weight | 200 | kg |

| Round Tube Automatic Loading Parameters | Φ15 – Φ220 | mm |

| Square Tube Automatic Loading Parameters | 15 – 150 | mm |

The right to make changes to dimensions, construction, and equipment is reserved. ISO-9001-certified.

The technical data can vary based on the chosen configuration of the machine.

| Cutting Head | Han’s Laser | |

| Focus Mode | Automatic | |

| Cooling Mode | Water Cooled | |

| Piercing Mode | 3 Stage | |

| Laser Source | IPG (Germany) / MAX Photonics (China) | |

| Rack & Pinion | YYC (Taiwan) | |

| Speed Reducers | DESBOER (Japan) | |

| Servo Drives & Motors | Panasonic (Japan)/Innovance (China) | |

| Linear Guide Rails (X & Y-axis) | ROUST (Germany) | |

| Computer | Industrial X64-based PC | |

| Operating System | Windows 10 64 bit | |

| CNC Software | FSCUT3000S | |

| Display Size | 20″ | |

| Electrical System | Schneider (France) | |

| Cooling Device | Dual Circuit Industrial Chiller | |

| Laser Source Enclosure | HAN’S Laser A/C Cabinet | |

The technical data can vary based on the chosen configuration of the machine.

control system’s main features

Han’s laser control system is based on the FSCUT3000S control system, which is a fully featured open-loop control system specially launched for the tube processing industry. With convenient installation, simple debugging, excellent performance and complete solutions, it is the most popular fiber laser cutting control system with the highest market share at present. Combining this with Han’s decades of R&D and extensive parameter database create an amazing value tube for Han’s laser cutting machine.

The FSCUT3000S control system has the following features:

-

Insensible Perforation: It supports any combination of multi-level perforation, segmentation or progression.

-

Compatible: It supports the communication control of all mainstream lasers in the market.

-

Han’s laser Powerful: It has complete one-button functionality and is very simple to use.

-

Han’s laser Advanced Technology: Support advanced processes such as cooling point, sharp corner ring path, bend relief, etc.

-

Intelligent Barrier Avoidance: Supports air movement, obstacle avoidance and leapfrog intelligent judgment.

-

Han’s laser Open-loop Control System: It supports automatic applications such as simple scheduling, virtual multi station, code scanning and mapping.

Han’s Industrial Fiber Laser

Han’s own automatic

focusing laser cutting head

Han’s Laser are equipped with Fully self-developed fiber laser cutting heads.

This means that the machines are developed as a whole idea rather than individual components

making integration seamless.

Strict beam shaping and robust mechanics combined with fixed optical ratio lens, coupled with

the non-contact high automatic tracking system of Han’s SMC capacitor mean Han’s Laser

cutting heads have established themselves right at the top of local markets and have become

the go to head on Han’s fiber lasers.

choice of laser source

IPG PHOTONICS

IPG Photonics is the world leader in fiber laser technology. The beam is of the highest quality, allowing constant cutting with extreme precision.

IPG features a compact, water-cooled, modular design, which allows for easy maintenance and relocation as required. IPG also boasts a class-leading wall plug efficiency of 50%, making them the industry standard for good reason.

Key components are tested or burned-in for hundreds of hours, and in the end, IPG only use the best components that have passed stringent control standards. IPG Photonics is certified ISO 9001:2008, giving customers the assurance that their business processes are both well-documented and conform to the same standards of quality upheld by most of the world’s largest and most highly regarded companies.

MAX PHOTONICS

Maxphotonics Multi-Module CW Fiber Laser adopts water cooling, modular design, compact structure, highly integrated system, maintenance-free and high reliability.

The Han’s laser laser power is continuously adjustable, with high electro-optical conversion efficiency, high beam quality, and high laser stability. It is an ideal laser source for thick-plate laser cutting, laser welding, laser cladding, surface heat treatment and other applications.

CW Fiber Han’s laser Laser adopts optical fiber with QBH head output CW Fiber Laser adopts optical fiber with LOE head output, which can be used with laser processing heads, galvanometers, etc. for system integration with robots and machine tools. It is widely used in hardware, medical, automotive, marine, aviation, construction machinery and other industries.

HAN’S FIBER LASER

The self-developed core device of Han’s HL fiber laser has the advantages of good beam quality, high electro-optical conversion rate, wide modulation frequency range, strong anti high reaction ability, high stability and reliability, good processing effect, maintenance free operation, etc.

Good beam quality and electro-optic conversion efficiency are far higher than those of domestic peers.

The power attenuation caused by the non photon darkening effect is less than ± 1% of the full power fluctuation. doped non attenuation gain fiber is used.

The maximum modulation frequency is 50kHz, and the modulation frequency range is wide.

Han’s laser High frequency perforation of stainless steel and aluminum alloy with a diameter of more than 10mm is faster, and fine sheet processing and other fields.

TRANSMISSION SYSTEM

The whole system adopts high end components to ensure the highest speed transmission while maintaining precision, stability, low failure rate and long service life.

Excellent internal quality achieves high standard machining dimensional accuracy, ensuring long-term stable operation of the equipment.

Desboer Reducers

Desboer high precision reducer, with high precision, high torsional stiffness, high reliability, low noise and longer service life, is more suitable for long-term high speed operation applications.

Roust Linear Guides

Roust precision linear guide rail has built a complete set of high-precision transmission system. Excellent internal quality has achieved high standard machining dimensional accuracy, and ensured the long-term stable operation of the equipment.

YYC Precision Rack

K. H/YYC precision helical rack, wear-resistant, high precision, smooth operation, better stability, can maintain accuracy for a long time and prolong service life.

Innovance Servo Motor

Inovance high-end servo motor meets the requirements of high speed, high precision, high quality and high productivity.

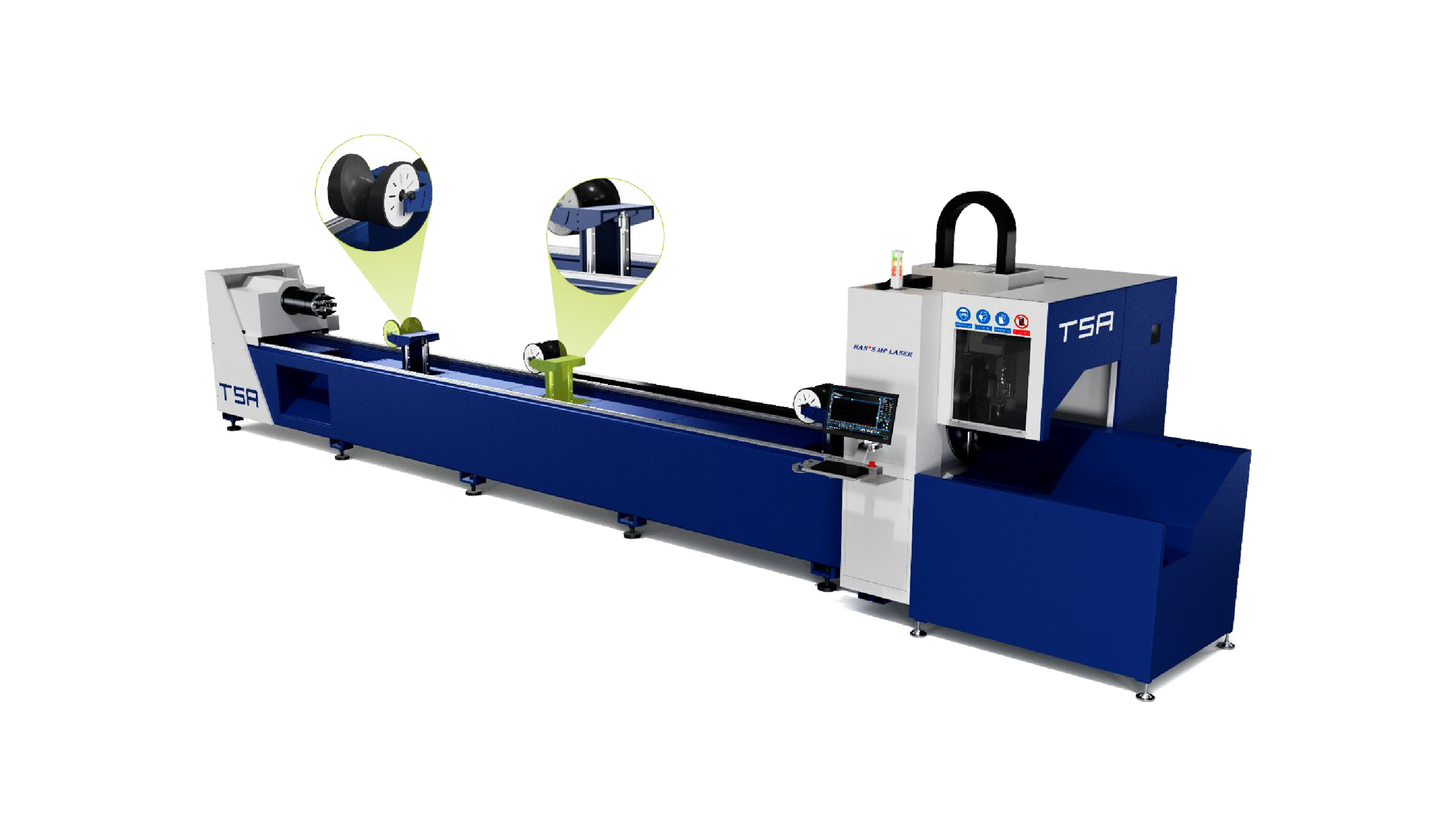

pneumatic chuck

Han’s independently designed and developed pneumatic chuck and push type pipe cutting method ensure precision processing accuracy and efficiency.

Front Chuck

- The chuck sliding block is optimized to maximise the maintenance interval.

- Precision sliding block clamps in perfect symettry. All moving parts have been heat treated for hardness. High durability and accuracy are guaranteed.

- The supporting span of the claw is reasonable, the rigidity of the claw is strong, and the clamping center is stable when rotating to ensure processing accuracy.

Rear Feeding Chuck

- The stroke of the rear jaw is 40mm, the keyway is positioned, and the jaw is easy to replace.

- Standard air blowing and optional dust extraction channel can effectively reduce dust accumulation and potential jamming, with simple maintenance.

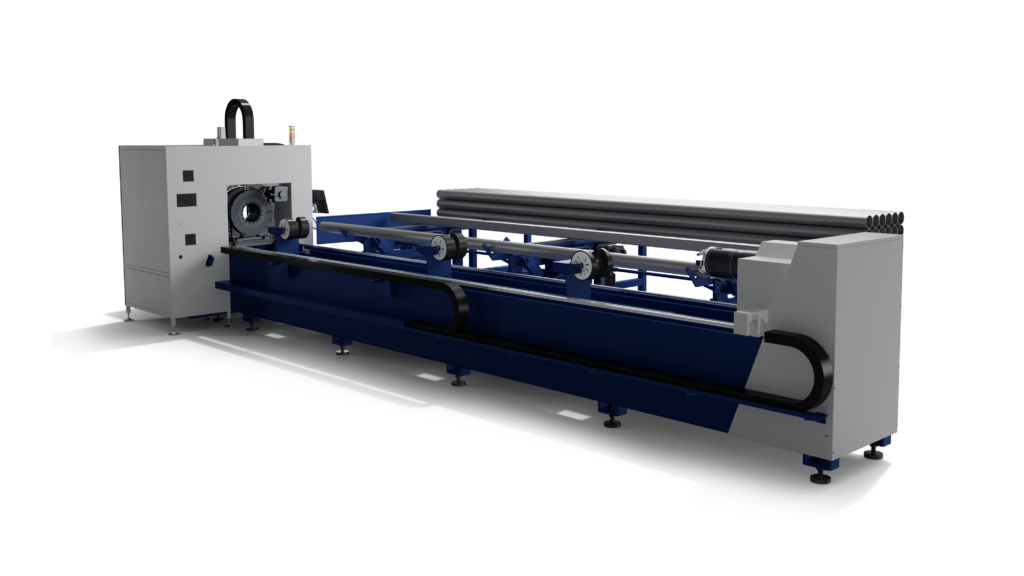

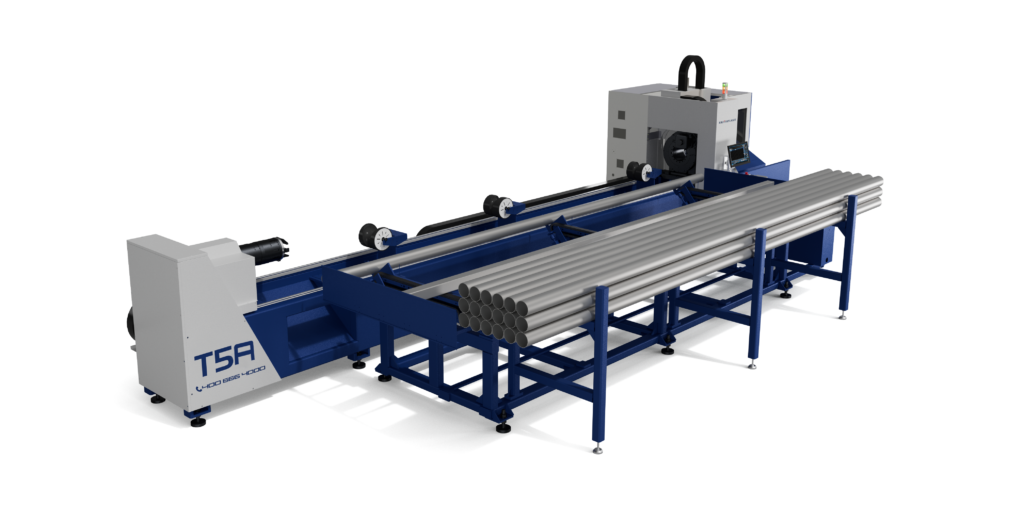

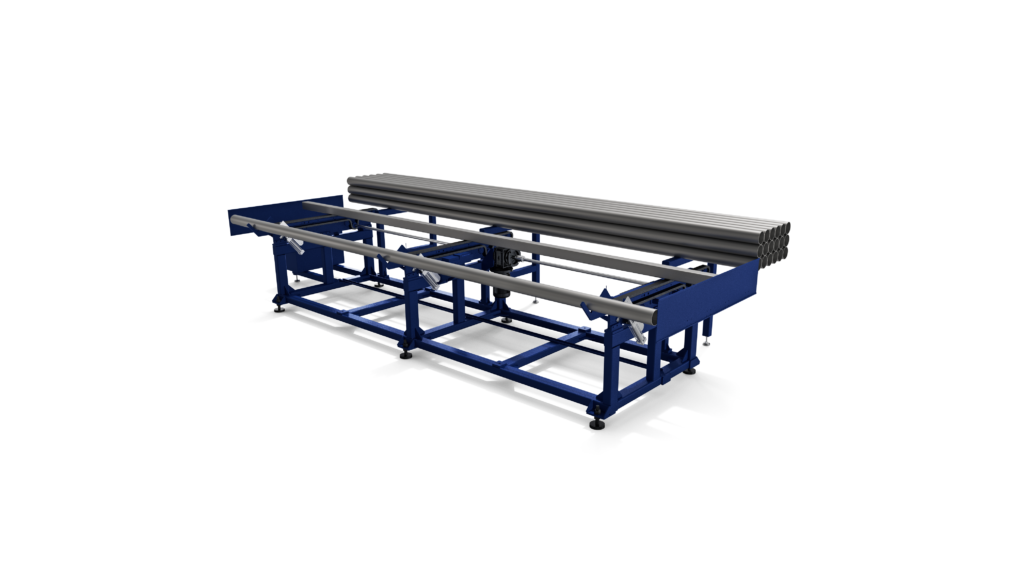

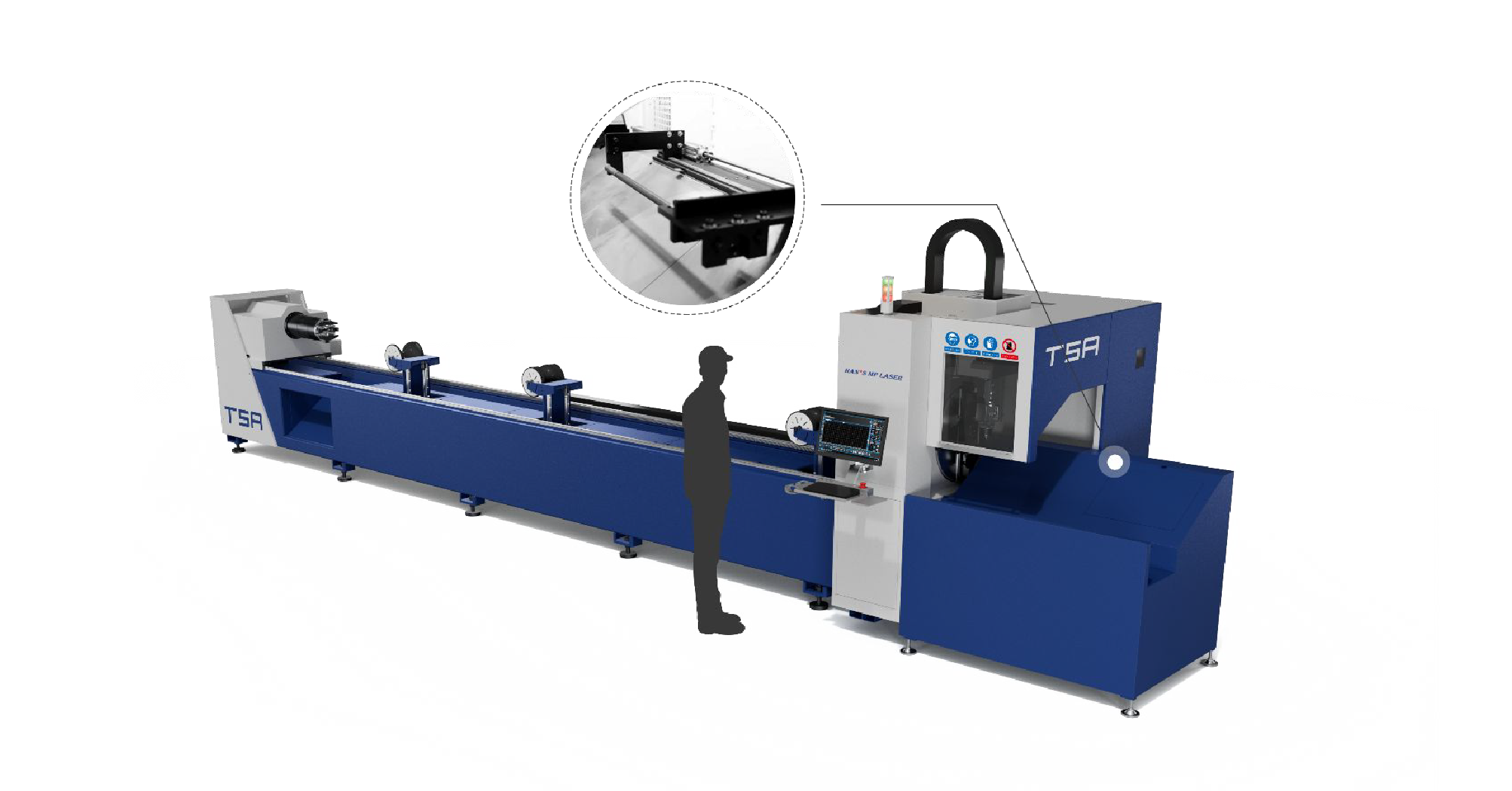

Semi Automatic Feeding (Optional)

- Manually place individual tubes from material storage rack onto the chain infeed.

- The chain moves tubes towards the front of the machine, and the cylinder lifts and separates one pipe at a time to be loaded.

- The feeding mechanism sends the pipes to the cutting machine.

- The roller supports of the pipe cutting machine rise to support the tube, and the feeding system returns while the rear chuck clamps the pipe.

- The rear chuck of the pipe cutter drives forward to begin tube processing.

Flexible Console

- The console can be moved to the optimal location for comfortable operation.

- The operator can see important machine components and control them in real time.

Anti-Slag Device (Optional)

- A consumable pipe is inserted inside the end of the workpiece, and extends underneath the laser path to protect the opposite side from any heat or sparks that may impact the finish.

Roller Supports

- Precision levelled roller supports assist in the stable infeed of the work pieces and especially assist in accurate cutting of longer products.

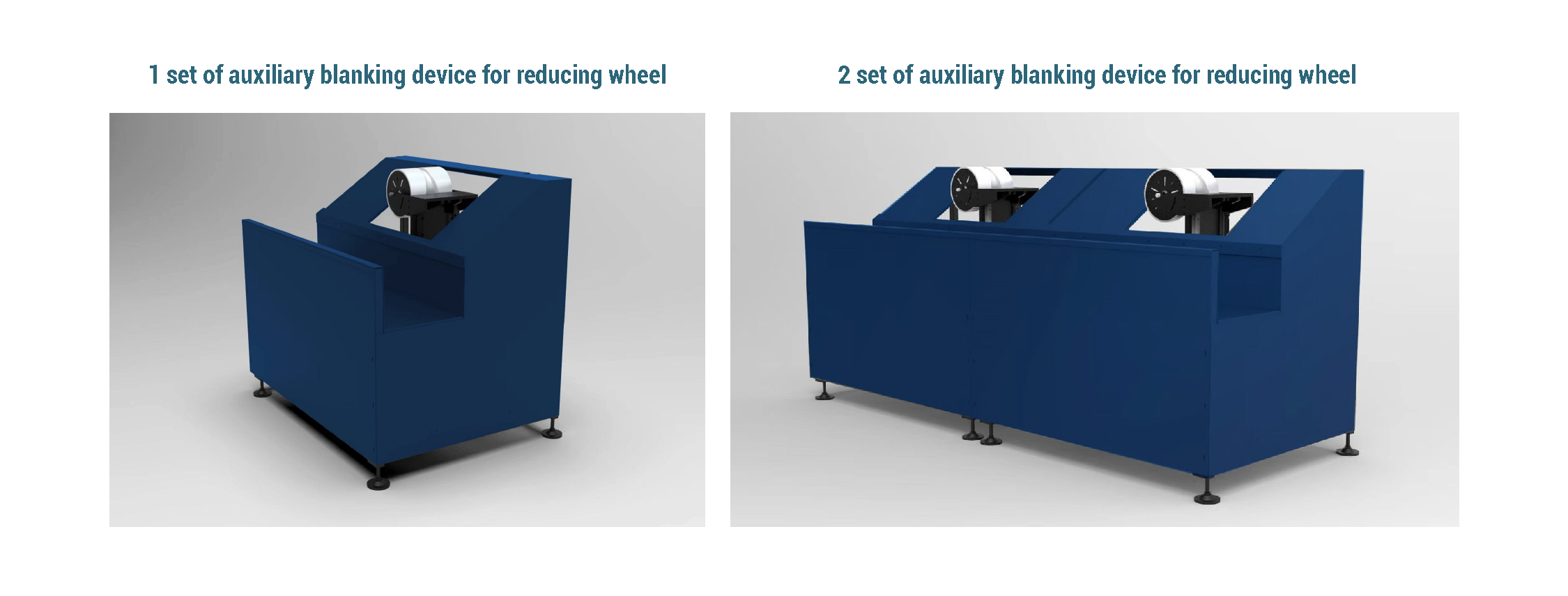

Auxiliary Blanking Device (Optional)

- The blanking device is attached with a storage structure to facilitate blanking.

- The reducer support structure is used for the blanking of raw materials and the support of long work pieces during the processing of laser pipe cutting machine profiles, instead of manual blanking.