Han’s Laser Cutting Machine Description.

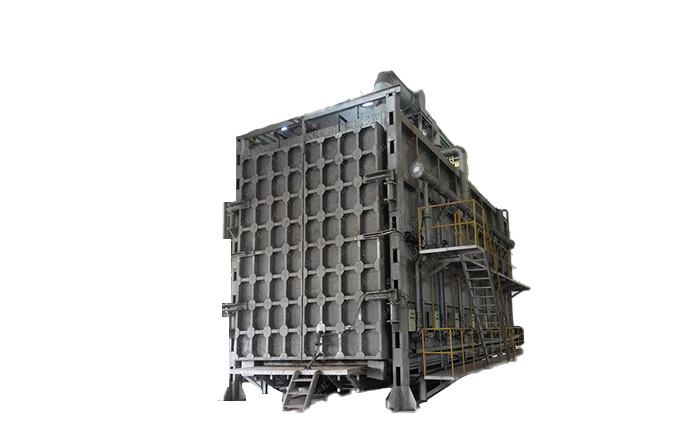

➢ Solve the equipment demand of domestic high-end customer.

➢ Fast speed, low energy consumption and high safety are used by customers who need low energy consumption and high efficiency.

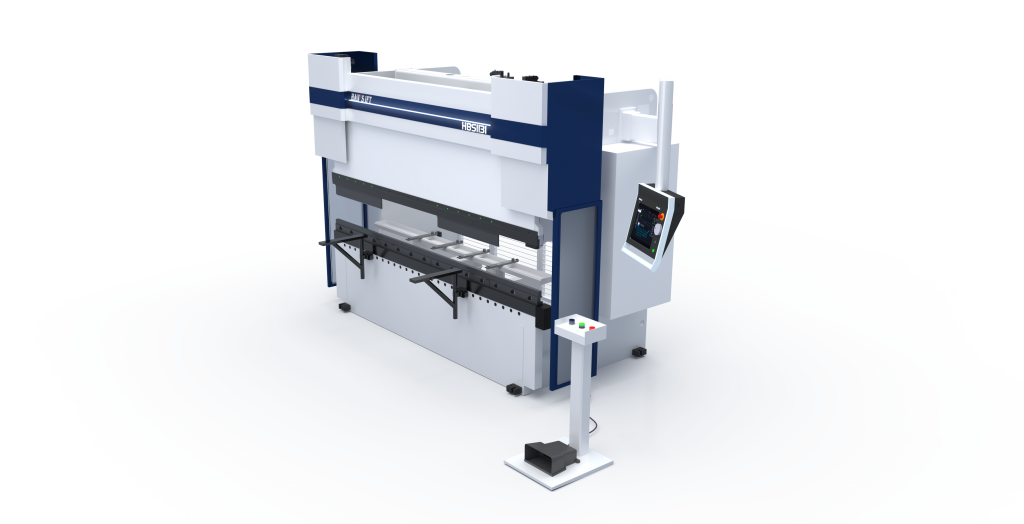

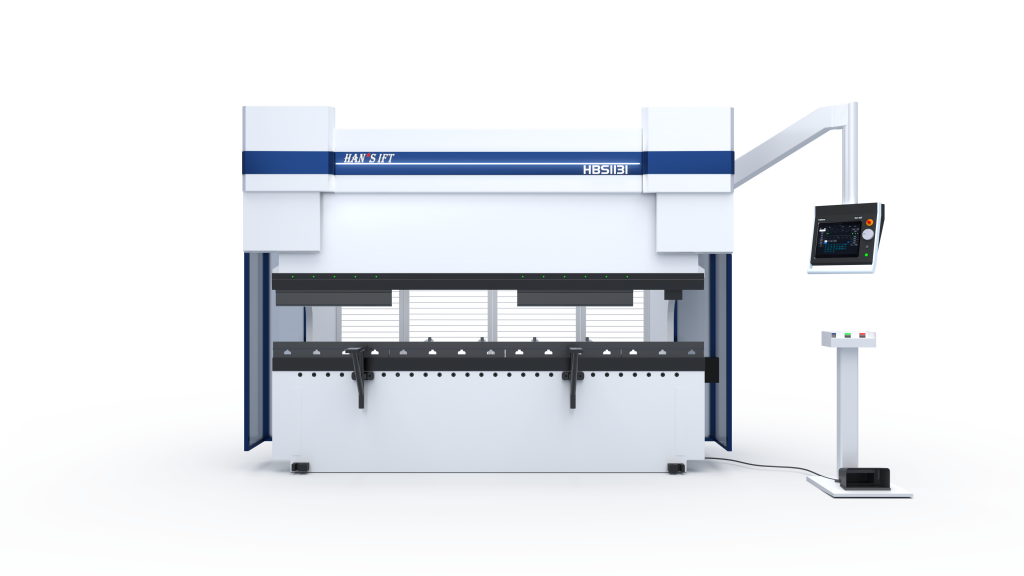

➢ Han’s laser machine is designed by experienced R&D teams at home and abroad, with fashionable appearance, stable performance, high accuracy and simple operation.

➢ The software and hardware of the Han’s laser tool are high-end configurations, with high-cost performance.

➢ High-standard production system and strict quality control will provide customers with high quality and reliable bending machines.

➢ Global integrated sales system, large coverage of after-sales service team, ready to respond to customer needs.

High: high degree of intelligence, high precision, high configuration, high security, high stability, high-cost performance.

Strong: The team has rich experience and strong R&D ability (first-class top team, members are industry experts.

Handsome: handsome appearance (new appearance design, a touch of Han’s laser blue consistent bending action, safe, mature and reliable.

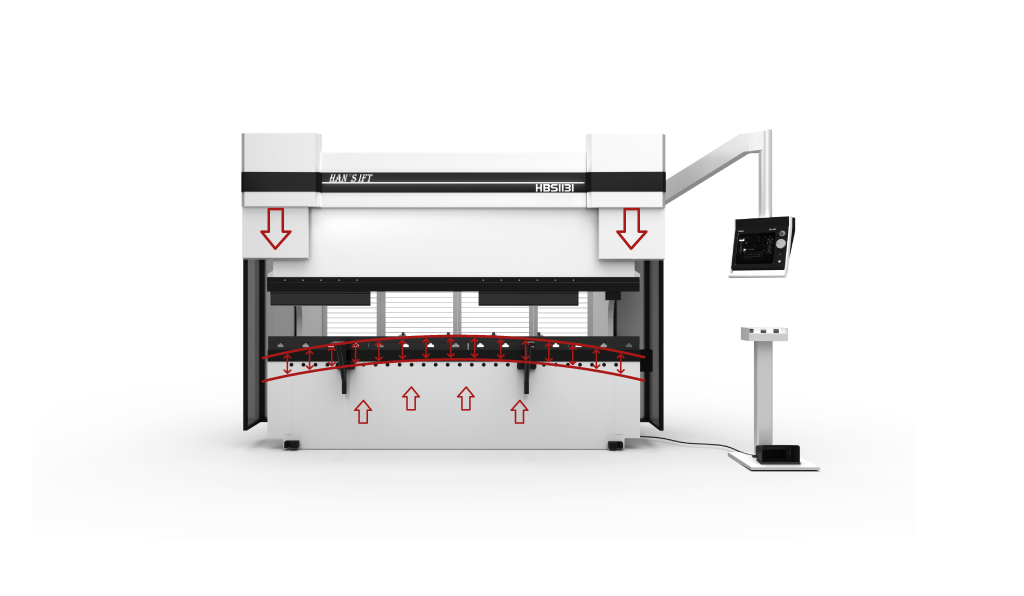

Accurate & Fast:

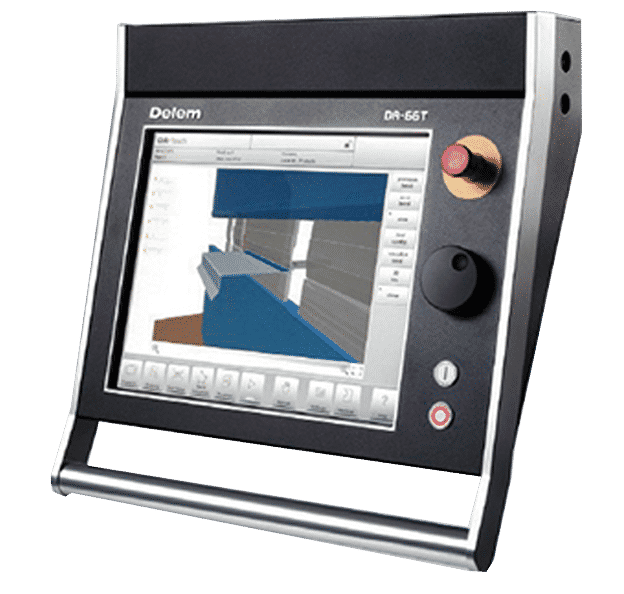

CNC AXIS

400Ton and below:

4+1: Y1, Y2, X, R +V

6+1: Y1, Y2, X, R, Z1, Z2 +V

Above 400Ton:

3+1: Y1, Y2, X +V

➢ Machine Axis: Y1, Y2, V (Essential)

➢ Backgauge Axis: X (Essential), R, Z1, Z2 (Optional)