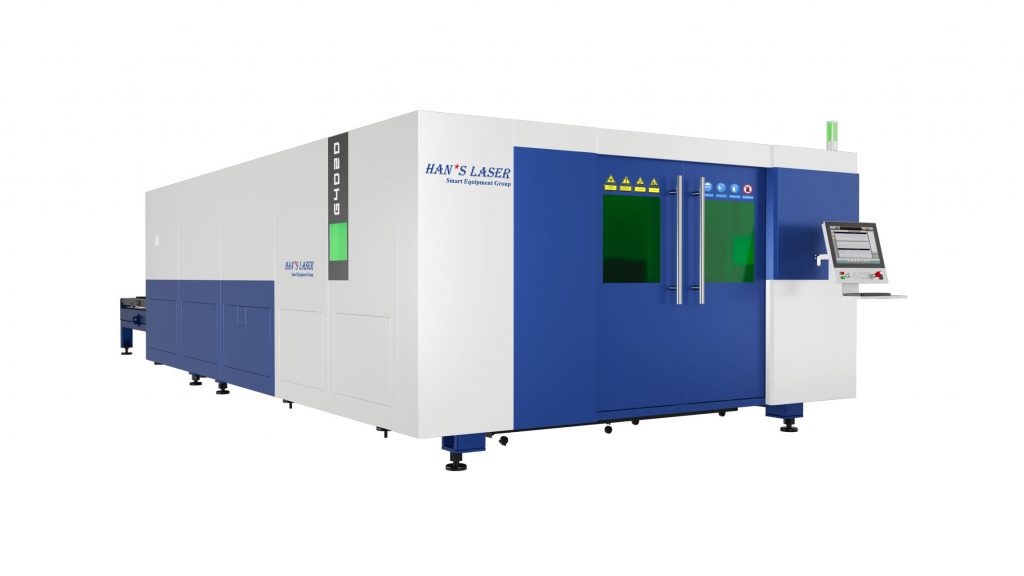

meet the HAN’S LASER g series

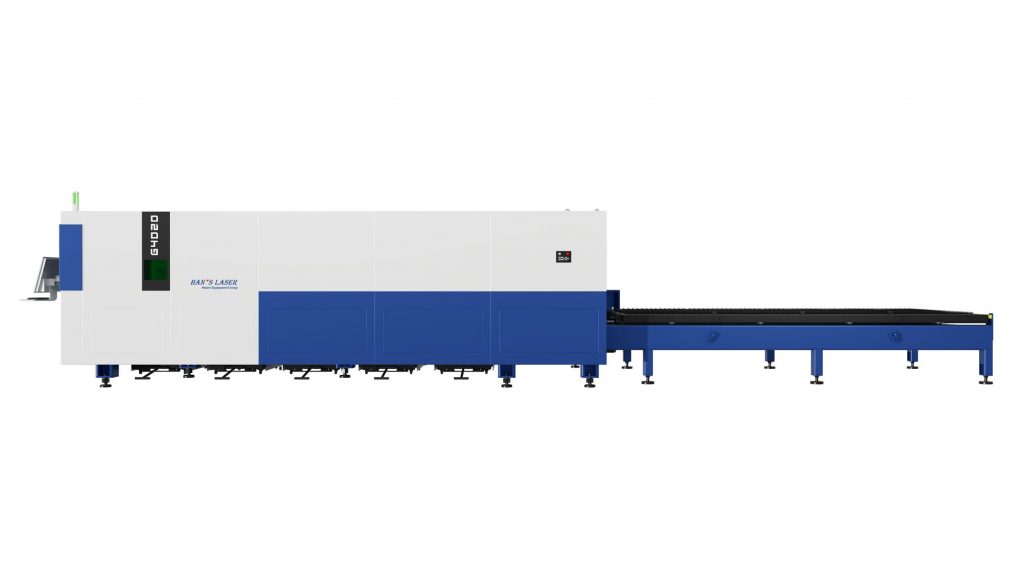

The G Series Fiber Laser Cutting Machine adopts a gantry dual drive structure, with the overall bed body welded and annealed from carbon steel, the crossbeam is processed and formed from high strength aluminum alloy, and heat treated for extra strength and rigidity whilst maintaining it’s lightness.

Components are processed by rough machining, vibration aging treatment, and precision machining helping to achieve extremely high form and position tolerance accuracy.

In terms of transmission, it is equipped with high-efficiency transmission mechanisms, precision reducirse, grinding gears and racks and high precision linear guides which are both extremely rigid and highly accurate. This ensures the long term stable operation of the equipment.

The Han’s SMC bus based CNC system, independently developed by Han’s Laser, forms a precision CNC fiber laser cutting machine that integrates disciplines such as laser cutting, precision machinery, and CNC technology.

Benefits

- The new hollow structure bed has a solid, stable and longlisting structure that never deforms due to heat.

- Independently developed HANS-SMC bus CNC system is purpose built for the Hans G Series fiber laser and offers higher control accuracy, stability, reliability, smooth operation, and a friendly and comfortable interface.

- Advanced cutting functions such as automatic edge seeking, co edge cutting, micro linking, variable frequency perforation, and non-sensitive perforation are all standard.

- Fully customized and refined components ensure stable transmission with high accuracy and precise repeated positioning.

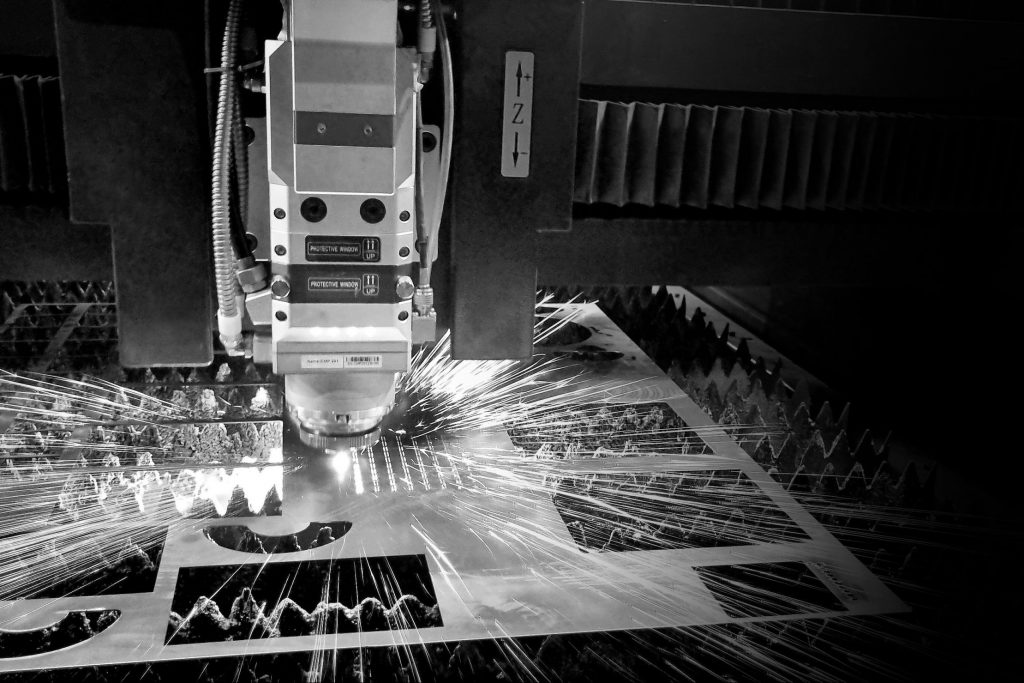

STABLE CUTTING

- Carbon Steel: 0.5~50mm

- Stainless Steel: 0.5~40mm

- Aluminum: 0.5~30mm

- Copper: 0.5~12mm

Details

CAPABILITIES:

- The G series machines are designed for medium and thin sheet metal processing and industrial customers, equipped with a family bus type full function CNC system, paired with absolute value servo motors, high precision linear guide rack reducer transmission components, 2.2G high acceleration performance, 120m/min high positioning speed, outstanding performance, excellent dynamic performance, efficient and stable cutting, can be matched with 3kw~12KW.

- Efficient Cutting: The bus type fully functional CNC system

improves cutting efficiency by 20%. - Gantry Structure: Classic gantry structure, stable, sturdy and durable.

- Cost-effective: Efficiency accuracy cost-effective model.

- Application: Professional design mainly for medium and thin plates.

Specs

| 3015G | 4020G | 6020G | 6025G | 8025G | Units | |

| Machine Length | 9200 | 11000 | 15500 | 16000 | 20000 | mm |

| Machine Width | 3000 | 3500 | 3500 | 4200 | 4200 | mm |

| Machine Height | 2200 | 2200 | 2300 | 2300 | 2300 | mm |

| Nominal Sheet Size (X) | 3000 | 4000 | 6000 | 6000 | 8000 | mm |

| Nominal Sheet Size (Y) | 1500 | 2000 | 2000 | 2500 | 2500 | mm |

| X Axis Stroke | 3050 | 4050 | 6050 | 6050 | 8100 | mm |

| Y Axis Stroke | 1530 | 2030 | 2030 | 2520 | 2520 | mm |

| Z Axis Stroke | 250 | 250 | 300 | 300 | 350 | mm |

| X/Y Positioning Accuracy | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | mm/m |

| X/Y Repositioning Accuracy | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | mm |

| Max. Travelling Speed | 120 | 120 | 120 | 120 | 100 | m/min |

| Max. Accelerating Speed | 2.2 | 2.2 | 1.8 | 1.8 | 1.8 | G |

| Max. Accelerating Speed (Upgrade) | 2.5 | 2.2 | 2.0 | 1.8 | 1.8 | G |

| Max. Workbench Weight | 1500 | 3200 | 8000 | 9600 | 16000 | kg |

| Machine Weight (Approx.) | 5500 | 7000 | 12500 | 13000 | 20000 | kg |

Working tables up to 12000 x 3000 available upon request.

The right to make changes to dimensions, construction, and equipment is reserved. ISO-9001-certified.

The technical data can vary based on the chosen configuration of the machine.

| Cutting Head | Hans / Precitec | |||||||

| Focus Mode | Automatic | |||||||

| Cooling Mode | Water Cooled | |||||||

| Piercing Mode | 5 Stage | |||||||

| Laser Source | Han’s Laser / MAX Photonics Coractive (Canada) / IPG (USA / Germany) |

|||||||

| Rack | Svarog (Czech)/TOCO | |||||||

| Pinion | Hiwin/T-WIN/Roust world | |||||||

| Speed Reducers | Alpha (Germany) | |||||||

| Servo Drives & Motors | Innovance (China) | |||||||

| Servo Drives & Motors (Upgrade) | Bocsch Rexroth (Germany) | |||||||

| High Pressure Gas Circuit Control – Nitrogen, Air | Aventics (Germany) | |||||||

| Low Pressure Gas Circuit Control – Oxygen | Aventics (Germany) | |||||||

| Computer | Industrial X64-based PC | |||||||

| Operating System | Windows 10 64 bit | |||||||

| CNC Software | Han’s 801 CNC | |||||||

| Display | 18.5” Industrial Monitor | |||||||

| Laser and Cutting Head Cooling Device | Dual Circuit Industrial Chiller | |||||||

| Laser Source Enclosure | Han’s Laser | |||||||

The technical data can vary based on the chosen configuration of the machine.

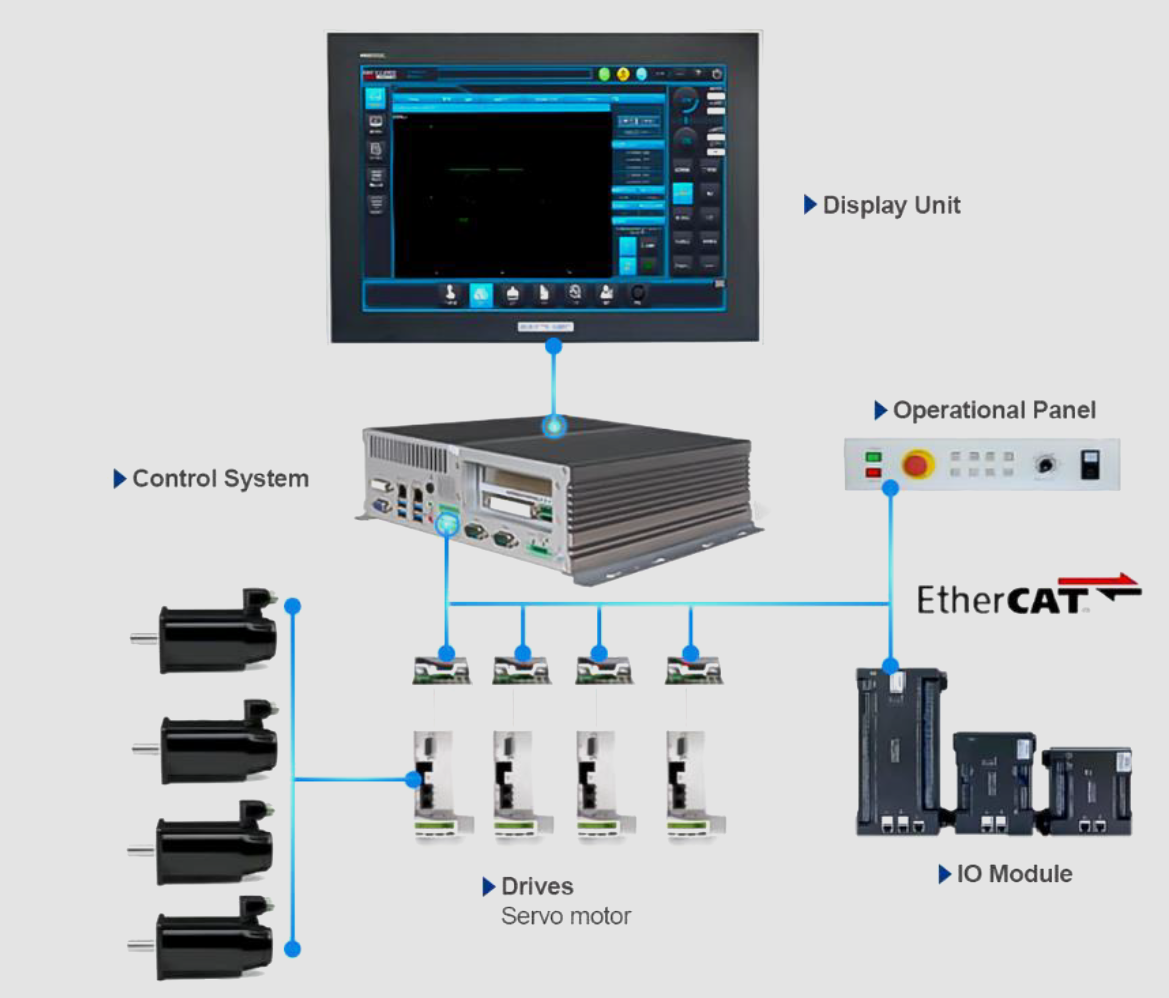

han’s fullY FEATURED cnc system

Adopt “Han’s SMC” open CNC system, which is based on Windows 10 Chinese and English operation interface, has the characteristics of high reliability, high performance, intelligence and networking, high-cost performance, simple operation and convenient use.

- A variety of cutting auxiliary gases can be easily and quickly converted through the CNC system.

- Possess a cutting process database, and design a humanized parameter interface, in which the process parameters can be modified in real time.

-

The Ethernet communication interface can directly communicate with the computer and transfer part program files.

- The CNC system that Han’s Laser offers is the most advanced and precise system available in the laser industry. This state-of-the-art system has cutting-edge capabilities that provide unmatched control and flexibility, making it a unique option for sectors that need accuracy and productivity. With Han’s Laser’s CNC system, users may easily obtain exceptional results in laser cutting, engraving, and marking. Its extensive toolkit and user-friendly interface offer an immersive experience where creativity and technology come together. This fully equipped CNC system from Han’s Laser demonstrates the company0s dedication to innovation and quality and sets new industry standards.

Han’s Industrial Fiber Laser

Han’s own automatic

focusing laser cutting head

Han’s Laser are equipped with Fully self-developed fiber laser cutting heads.

This means that the machines are developed as a whole idea rather than individual components

making integration seamless.

Strict beam shaping and robust mechanics combined with fixed optical ratio lens, coupled with

the non-contact high automatic tracking system of Han’s SMC capacitor mean Han’s Laser

cutting heads have established themselves right at the top of local markets and have become

the go to head on Han’s fiber lasers.

choice of laser source

IPG PHOTONICS

IPG Photonics is the world leader in fiber laser technology. The beam is of the highest quality, allowing constant cutting with extreme precision.

IPG features a compact, water-cooled, modular design, which allows for easy maintenance and relocation as required. IPG also boasts a class-leading wall plug efficiency of 50%, making them the industry standard for good reason.

Key components are tested or burned-in for hundreds of hours, and in the end, IPG only use the best components that have passed stringent control standards. IPG Photonics is certified ISO 9001:2008, giving customers the assurance that their business processes are both well-documented and conform to the same standards of quality upheld by most of the world’s largest and most highly regarded companies.

MAX PHOTONICS

Maxphotonics Multi-Module CW Fiber Laser adopts water cooling, modular design, compact structure, highly integrated system, maintenance-free and high reliability.

The laser power is continuously adjustable, with high electro-optical conversion efficiency , high beam quality , and high laser stability. It is an ideal laser source for thick plate laser cutting, laser welding, laser cladding, surface heat treatment and other applications.

CW Fiber Laser adopts optical fiber with QBH head output CW Fiber Laser adopts optical fiber with LOE head output, which can be used with laser processing heads, galvanometers, etc,for system integration with robots and machine tools. It is widely used in hardware, medical, automotive, marine, aviation, Construction machinery and other industry.

hAN’S FIBER LASER

Han’s Photon C series multimode group 4kW-30kW continuous fiber laser is equipped with a new high power optical module.

The module’s electro-optical conversion efficiency is higher than 40%, fundamentally reducing the overall power cost.

Equipped with a new generation of independently developed electronic control system, the equipment has stronger compatibility, simple and more user-friendly operation, real-time internal monitoring, fast data feedback response, and modulation pulse response in microseconds.

Strict beam quality control, supporting the application scenario analysis of Han’s laser experts, gives full play to the performance of the laser.

TRANSMISSION SYSTEM

The whole system adopts high end components to ensure the highest speed transmission while maintaining precision, stability, low failure rate and long service life.

Excellent internal quality achieves high standard machining dimensional accuracy, ensuring long-term stable operation of the equipment.

Wittenstein Speed Reducers

German Alpha Wittenstein Gear Reducers:

– 3 minutes of arc backlash,

– Tooth runout accuracy ≤ 0.015mm.

Alpha Wittenstein are known for their exceptional quality.

These same speed reducers have been installed on Han’s machines for years due to their reliability.

Rexroth (Germany)

Rexroth (Germany) bearing block and guide rail with a butt joint gap ≤ 0.02mm.

Rexroth’s high-quality linear guideways provide linear motion by re-circulating rolling elements between a profiled rail and a bearing block.

Güdel Rack and Helical Pinions

Advanced engineering and precision manufacturing have created the highest quality linear systems available today Swiss GÜDEL rack is manufactured to Grade Q6 with a tooth runout accuracy ≤ 0.015mm.

Servo Motors and Drives

High power Rexroth servo drives and motors, are used for large torque and zero lag.

Unbeatable performance when combined with Han’s Rexroth based 901 CNC system.

Ether CAT

han’s laser bus control system

Ether CAT digital quantity bus communication, system host, servo module, IO module and height adjustment module can be connected with only one network cable, which greatly avoids electromagnetic interference, has stronger control stability and higher transmission efficiency.

Han’s Laser Bus Control System is at the forefront of this revolution in laser technology, where accuracy and control are crucial. This advanced technology is made to provide laser applications unparalleled accuracy, adaptability, and efficiency. It conducts the complex dance of lasers with such ease that it guarantees their perfect harmony and precision.

In addition to being a technological wonder, Han’s Laser Bus Control System is an example of creativity and quality. It enables users to fully use laser technology thanks to its innovative features and user-friendly interface. This technology gives you control over any application, be it laser cutting, engraving, marking, or anything else, so you can easily get outstanding outcomes.

Ultra-High Power

Realize simple program coding without computer operation, reduce time and improve efficiency.

Batch Processing of Single Machine

After loading the processing task list, multiple processing of a single program or multiple programs can be realized.

Multiple Processing of Single Machine

Multiple plates are placed on a single workbench and single or multiple processing tasks are loaded to realize one-time processing plates.